Introduction: Defining the Rail Mounted Gantry Crane

In the high-stakes, fast-paced world of intermodal freight and container terminal operations, efficiency, precision, and reliability are non-negotiable. At the heart of this logistics symphony stands the Rail Mounted Gantry Crane (RMG) – a robust, track-bound workhorse engineered for the dense stacking and rapid transfer of shipping containers. Unlike its rubber-tired counterparts, an RMG operates on fixed, parallel rail tracks, offering unparalleled stability, lifting capacity, and suitability for automation. This technical deep-dive explores the design, functionality, and critical advantages that make the RMG a cornerstone of modern port and rail yard infrastructure.

What is a Rail Mounted Gantry Crane (RMG)?

ARail Mounted Gantry Crane (RMG) is a heavy-duty, fixed-path gantry crane designed for lifting, moving, and stacking shipping containers within a confined yard area. Unlike mobile cranes, it operates on a set of parallel steel rails installed on the ground. This rail-bound system provides a defined lane for longitudinal travel, while a trolley and hoist mechanism move transversely across its main girder to handle containers with high precision. RMGs are a cornerstone technology in modern intermodal terminals and port container yards, prized for their stability, high-density stacking capability, and seamless integration with automation systems.

https://www.zehuacranes.com/Efficient-Rail-Mounted-Container-Gantry-Crane-in-port.html

Technical Design and Core Components

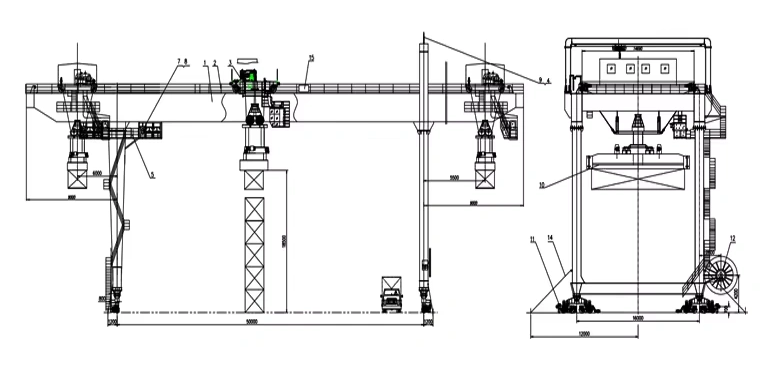

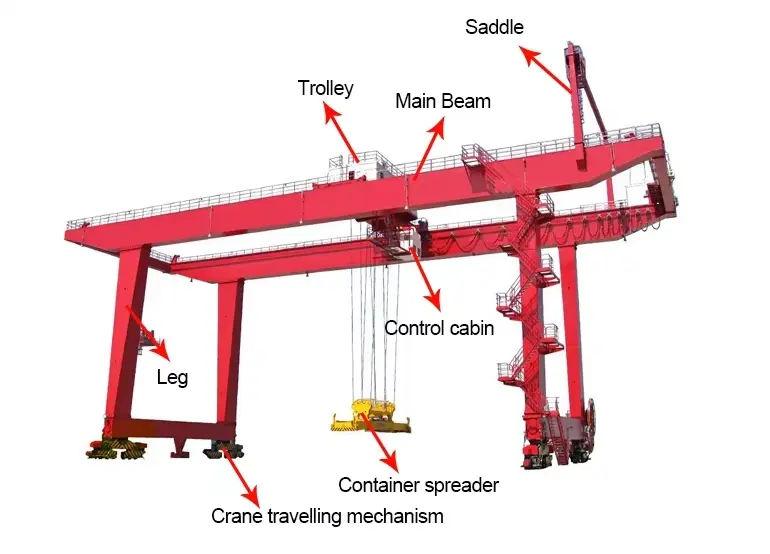

An RMG is a large, floor-mounted gantry crane that travels on dedicated rail tracks, typically spanning a defined stacking yard, rail loading area, or truck lane. Its design is optimized for continuous, high-cycle operation.

1. Structural Framework:

Main Girder (Bridge): The primary horizontal beam that spans the working width of the yard. It is designed for minimal deflection under full load, ensuring precision during container handling.

Legs / End Carriages: Vertical structures at each end of the girder that house the drive mechanisms (bogies) for longitudinal travel along the rails. Legs can be uniform or have different heights (semi-gantry) depending on yard layout needs.

Rail System: Heavy-duty, precisely aligned steel rails that provide the crane’s travel path. This fixed guidance system is fundamental to the RMG's accuracy and potential for automation.

2. Hoisting and Trolley System:

Trolley: Travels transversely across the main girder on its own set of rails. It carries the hoisting machinery.

Hoist Unit: The powerful winch system that raises and lowers the spreader. It features precise control for soft landing and high-speed cycling.

Spreader: A telescopic, twist-lock mechanism that attaches to the top corners of containers. Modern spreaders are adjustable to handle 20ft, 40ft, 45ft, and even twin-lift configurations.

3. Drive and Control Systems:

Electrification: RMGs are typically powered by conductor bars (collector systems) or cable reels running parallel to the tracks, providing continuous and reliable power without the emissions of diesel engines.

Drive Bogies: Wheelsets mounted on the end carriages, equipped with high-torque motors for acceleration, travel, and braking.

State-of-the-Art Control: Operators control the crane from a ventilated, soundproofed cab mounted on the trolley or via a remote control station. In Automated RMG (ARMG) systems, all movements are directed by a Terminal Operating System (TOS) using GPS, lasers, and optical character recognition (OCR) for fully unmanned operation.

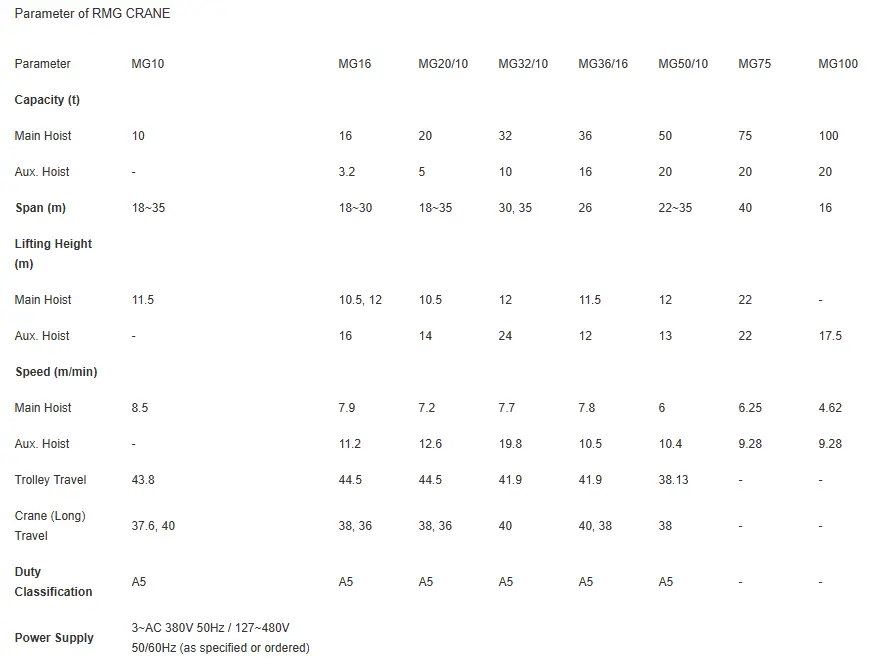

Key Technical Specifications and Capabilities

Lifting Capacity: Typically ranges from 35 to 50 metric tons under the spreader, capable of handling fully laden containers.

Span: Can span 6+1 (six container rows and one truck lane) or 7+1 configurations, and even wider for specialized yards.

Stacking Height: Capable of stacking containers 5-over-1 or 6-over-1 (5 or 6 high on the ground), maximizing yard density.

Operational Advantages and Applications

1. Superior Stability and Precision: The fixed rail system eliminates the sideways sway common in Rubber-Tired Gantries (RTGs), allowing for faster, more precise spotting of containers, especially in high-wind conditions.

2. High Density Stacking: RMGs are the ideal solution for maximizing storage space within a confined yard area due to their wide span and high stacking capability.

3. Ideal for Intermodal Integration: RMGs seamlessly serve both truck loading/unloading lanes and railcar loading/unloading tracks (acting as rail-mounted gantry cranes in the truest sense), making them perfect for inland intermodal terminals.

4. Pathway to Full Automation: The predictable, track-bound movement of an RMG makes it the preferred choice for terminal automation. Automated RMGs operate 24/7, optimizing throughput, reducing labor costs, and enhancing safety.

5. Environmental and Economic Efficiency: Electric power eliminates onsite emissions, reduces noise pollution, and leads to lower long-term operational costs compared to diesel-powered RTGs.

RMG vs. RTG: A Critical Comparison

While both serve container yards, the choice is strategic:

Flexibility vs. Stability: RTGs offer mobility and can be relocated, but RMGs provide superior operational stability and speed.

Cost Structure: RTGs have a lower initial capital cost but higher long-term fuel and maintenance costs. RMGs require significant upfront investment in rail infrastructure but offer lower operating costs and higher productivity over time.

Automation Suitability: RMGs are inherently better suited for automation due to their fixed travel path.

Conclusion

The Rail Mounted Gantry Crane is far more than just a lifting device; it is a sophisticated, high-throughput materials handling system that defines the efficiency of modern logistics hubs. Its combination of brute strength, pinpoint precision, and seamless integrability with automation technologies makes it an indispensable asset for any terminal or intermodal yard aiming to achieve peak operational performance, maximize density, and future-proof its operations. For port authorities, terminal operators, and logistics planners, investing in RMG technology is an investment in scalability, sustainability, and long-term competitive advantage.

FAQ: Rail Mounted Gantry Cranes (RMGs)

Q1: What is the fundamental difference between an RMG and an RTG?

The core difference lies in mobility and guidance. A Rail Mounted Gantry (RMG) runs on fixed, embedded steel rails, confining it to a predetermined lane but granting exceptional stability. A Rubber-Tired Gantry (RTG) crane moves on pneumatic tires, giving it the flexibility to drive between container stacks and change lanes, but with less stability and precision. RMGs are typically electrified via conductor bars, while RTGs are often diesel-powered, though hybrid/electric RTGs exist.

Q2: Why are RMGs considered more suitable for automation than RTGs?

RMGs are the preferred choice for automation due to their fixed and predictable path of travel. The defined rail track eliminates the positioning variables and complex navigation required for a mobile RTG. This allows Automated RMGs (ARMGs) to be controlled with high precision by a Terminal Operating System (TOS) using simple, reliable sensors for positioning, making full, unmanned 24/7 operation more feasible, safe, and cost-effective.

Q3: What are the main cost considerations when choosing an RMG system?

Choosing an RMG involves a higher initial capital expenditure (CAPEX) compared to an RTG fleet. This cost includes the crane itself and the significant civil works for installing the heavy-duty concrete foundation and rail network. However, RMGs offer a lower operational expenditure (OPEX) over their lifetime due to energy-efficient electric operation (vs. diesel), lower maintenance requirements than complex tire and drivetrain systems, and higher productivity, leading to a better long-term ROI, especially in high-throughput facilities.

Q4:What industries, beyond major ports, use RMG technology?

While container ports are the primary user, RMG technology is also effectively deployed in:

Inland Intermodal Terminals: For transferring containers between stack trains and trucks.

Heavy Industry and Manufacturing: For handling large, heavy raw materials like steel coils, timber, or bulk product modules in factory yards.

Logistics Hubs and Freight Corridors: Large-scale distribution centers that require dense, systematic storage of containerized goods.

HENAN ZEHUA HEAVY INDUSTRY EQUIPMENT CO., LTD

Email: sale@zehuacranes.com

Website: [https://www.zehuacranes.com/]

Whatsapp:86-19562739544