1. Gantry Crane

A Gantry Crane is characterized by its self-supporting structure. It features a hoist mounted on a trolley that travels along a horizontal bridge, which is supported by two or more rigid legs running on ground-level rails or wheels.

Key Technical Design & Variants:

Full Gantry Crane: Has two legs both running on ground rails. Used for heavy-duty, wide-span outdoor applications.

Semi-Gantry Crane: One leg runs on an elevated rail attached to a building column, while the other runs on a ground rail. Ideal for servicing the edge of a building.

Portable Gantry Crane: A lightweight, often adjustable-width unit with casters for mobility within a workshop. Not rail-bound.

Technical Speciications & Considerations:

Support Structure: Independent; requires no overhead runway beams, but needs a firm, level floor or foundation for rails.

Load Capacity: Ranges from <1 ton (workshop models) to over 500 tons (shipyard gantries).

Span: Defined by the distance between the legs. Can be very wide for outdoor yards.

Duty Class: Typically Class A (Standby) to Class D (Heavy Service).

Power Systems: Electric (via festoon/busbar for rail-mounted) or manual/pneumatic for small portable units.

Primary Applications: Shipbuilding and repair yards, outdoor storage laydown areas, manufacturing assembly lines where floor space is available, construction sites, and modular applications where permanent overhead support is absent.

Advantages:

No dependence on building structure.

Ideal for outdoor use and covering large areas.

Can be relocated (especially portable versions).

Disadvantages:

Consumes valuable floor space.

Ground rails can present trip hazards and require maintenance.

Generally offers slower travel speeds compared to top-running bridge cranes.

2. Jib Crane

A Jib Crane is a type of crane where a horizontal member (the jib or boom) supports a movable hoist. This boom is mounted either to a wall or to a floor-mounted pillar. It provides rotational coverage within a confined circular area.

Key Technical Design & Variants:

Wall-Mounted Jib Crane: Bracketed to a building column or reinforced wall. Provides 180° or 200° of rotation.

Floor-Mounted Pillar Jib Crane: Mounted on a freestanding, foundation-supported column. Provides full 360° rotation.

Mast-Style Jib Crane: Features a column supported by both floor and ceiling mounts, reducing foundation requirements and allowing for higher capacities and spans.

Articulating Jib Crane: Has a two-part, knuckle-style boom, offering greater flexibility for reaching over obstacles, typically with lower capacities.

Technical Specifications & Considerations:

Support Structure: Building wall/column or dedicated foundation.

Load Capacity: Commonly from 250 kg to 5 tons, with some heavy-duty models reaching 15+ tons.

Span (Reach): The horizontal distance from the pivot center to the hoist hook. Typically ranges from 2m to 10m.

Rotation: Manual (slewing bearing) or electric (gear-driven).

Duty Class: Generally Class A-C (Light to Moderate Service).

Primary Applications: Machine loading/unloading, workstation material handling (e.g., feeding parts to a CNC machine), assembly stations, service bays, and any localized, repetitive lifting task.

Advantages:

Excellent space efficiency for localized tasks.

Provides precise load placement.

Lower cost for point-of-use lifting.

Simple installation (for smaller models).

Disadvantages:

Limited, circular coverage area ("spot welder" of cranes).

Cannot transfer loads between workstations.

Foundation requirements for floor-mounted models can be significant.

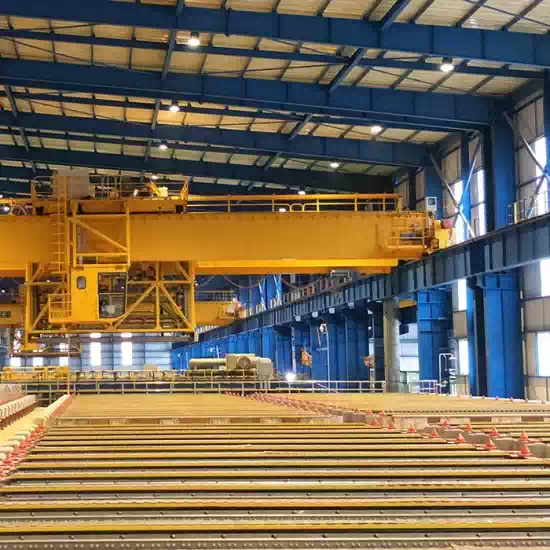

3. Bridge Crane (Overhead Bridge Crane)

The Bridge Crane, often synonymous with the term "overhead crane," is the most common type found inside factories. It consists of a hoist and trolley that travel laterally along a bridge beam, which itself moves longitudinally on runway rails seated atop supporting structures.

Key Technical Design & Variants (Based on Support):

Top-Running Bridge Crane: The crane bridge runs on rails mounted on top of runway beams supported by building columns or freestanding columns. This offers the highest hook height and is used for the heaviest loads (1 ton to 500+ tons).Under-Running Bridge Crane (Underhung): The crane bridge wheels run on the bottom flange of runway beams, which are suspended from the roof structure. This allows integration with monorails and is ideal for light to medium-duty applications (up to ~15 tons).

Technical Specifications & Considerations:

Support Structure: Requires robust overhead runway support—either building steel or dedicated crane support columns.

Load Capacity & Span: Extremely wide range. Capacity is a function of bridge and runway beam design. Spans can cover entire building bays.

Hook Height: Maximized in top-running designs.

Duty Class: Can be specified from Class A (Infrequent use) to Class F (Continuous severe duty) for process cranes in metals industries.

Control: Pendant, radio remote, or fully automated operation.

Primary Applications: Virtually all heavy industrial manufacturing: metal fabrication, paper mills, automotive plants, warehouses with very heavy unit loads, and assembly halls.

Advantages:Uninterrupted use of floor space beneath the crane.

Highest efficiency for moving loads throughout a rectangular bay area.

Designed for the most severe duty cycles and heaviest capacities.

Superior hook height (top-running type).

Disadvantages:

Highest initial cost and structural requirements.

Complex installation often requiring building modification.

Not suitable for outdoor use unless enclosed.

Comparative Summary & Selection Guide

| Feature | Gantry Crane | Jib Crane | Bridge Crane (Overhead) |

|---|---|---|---|

| Support | Self-supported (legs on floor) | Wall or Floor | Overhead Runway Beams |

| Coverage | Large rectangular area (yard/bay) | Circular area around pivot | Full rectangular building bay |

| Typical Use | Outdoor / Large Indoor Areas | Point-of-Use Workstation | Factory-Wide Material Flow |

| Floor Space | Consumes floor space | Minimal footprint | Zero footprint obstruction |

| Load Capacity | Low to Extremely High | Low to Medium | Medium to Extremely High |

| Ideal For | Where no overhead support exists | Localized, repetitive lifts | High-throughput, bay-wide lifting |

How to Choose:

Choose a Jib Crane for repetitive lifts within a single workstation or machine.

Choose a Bridge Crane for moving materials across the length and width of a production or storage bay inside a building.

Choose a Gantry Crane for outdoor applications, temporary sites, or indoor areas where installing overhead runways is structurally impossible or cost-prohibitive.

Conclusion

Understanding the distinct engineering principles and applications of Gantry, Jib, and Bridge Cranes is essential for designing an efficient and safe material handling system. The jib crane is your precision tool for a single point, the bridge crane is your high-capacity workhorse for plant-wide movement, and the gantry crane is your flexible solution for areas lacking overhead infrastructure

Q1: What is the fundamental structural difference between these three crane types?

A: The core difference lies in their support structure:

Gantry Crane: Freestanding, supported by legs that run on floor-mounted rails or wheels.

Jib Crane: Mounted to a fixed point—either a building column/wall (wall-mounted) or a foundation on the floor (floor-mounted/mast-style).

Bridge Crane (Overhead): Supported from above by runway beams attached to the building's roof or support columns.

Q2: Which crane type is best for outdoor use?

A: Gantry Cranes are the definitive choice for most outdoor applications (e.g., storage yards, shipping ports). Their self-supporting design requires no building infrastructure and can withstand weather. Bridge cranes are almost exclusively indoor, and jib cranes are primarily indoor workstation tools

Q3: Gantry Crane vs. Bridge Crane: Which is better for my indoor facility?

A: The choice hinges on your building:

Use a Bridge Crane if your building has (or can be reinforced to have) strong overhead support. It frees up all floor space and is generally more efficient for high-traffic indoor bays.

Use a Gantry Crane if your building has a weak roof structure (like some older warehouses), has no columns, or if you need the flexibility to later reconfigure or relocate the crane easily. The trade-off is lost floor space under the legs.