Introduction

The skyline of any major shipyard is dominated by colossal steel structures that move with surprising grace: shipyard cranes. More than just machinery, these are the indispensable titans of maritime construction, the linchpins in the complex process of building, outfitting, and launching some of the largest man-made objects on the planet. This article delves into the world of these engineering marvels, exploring their types, functions, and the incredible technology that allows them to handle loads weighing thousands of tons.

What is a Shipyard Crane?

A shipyard crane is a type of heavy-duty, specialized lifting equipment engineered for the construction, repair, outfitting, and dismantling of ships and other large marine structures. It is the backbone of a modern shipyard, and its capabilities directly determine the size and complexity of vessels a yard can handle.

Distinct from standard cranes, shipyard cranes are characterized by three key features:

Exceptional Lifting Capacity: Ranging from dozens to over 2,000 metric tons, they are designed to hoist massive pre-fabricated hull blocks, multi-hundred-ton ship engines (main propulsion units), and complete superstructures.

Vast Operational Range: To cover expansive construction docks and assembly areas, they feature significant lifting heights and long spans.

Precision Control: Handling multi-million dollar components requires surgical precision, with fine-control mechanisms enabling millimeter-accurate positioning for fitting.

Key Industries and Applications for Shipyard Cranes

The technology and principles of shipyard cranes extend beyond traditional "shipyards" to various heavy industries requiring massive load handling.

| Industry Sector | Primary Applications | Common Crane Types |

|---|---|---|

| 1. Shipbuilding & Offshore Construction | - Commercial Shipbuilding: Lifting hull blocks, main engines, hatch covers, superstructures. - Offshore Platforms: Assembling modules for drilling rigs, foundations for offshore wind turbines. - Naval Construction: High-precision and secure lifting for military vessels. |

Goliath Gantry Cranes, Semi-Goliath Cranes, Tower Cranes |

| 2. Ports & Terminals | - Heavy Lift / Break-bulk Terminals: Handling project cargo (e.g., locomotives, wind turbine components). - Ship Repair & Conversion: Serving dry docks for removing old parts and installing new equipment. |

Large Portal Slewing Cranes, Floating Cranes, Mobile Harbor Cranes |

| 3. Heavy Machinery & Construction | - Power Plant Construction: Installing giant pressure vessels for nuclear/thermal plants, generator stators. - Bridge Building: Erecting pre-cast bridge segments. - Heavy Industry: Positioning large manufacturing equipment. |

Large Crawler Cranes, Gantry Cranes, Specialized Lift Systems |

| 4. Ship Recycling | - Dismantling decommissioned vessels at docks or beaches, moving cut sections like bows, sterns, and steel plates. | Gantry Cranes, Floating Cranes, Large Crawler Cranes |

The Core Function: Why Shipyard Cranes are Indispensable

At its heart, a shipyard crane is designed for one primary purpose: to lift and maneuver extraordinarily heavy and oversized components with pinpoint precision. Modern shipbuilding relies on the modular construction method, where a vessel is built in large pre-fabricated sections or "blocks." These blocks, often weighing several hundred tons, must be transported from fabrication shops, carefully lifted over other structures, and aligned with millimeter accuracy for welding.

Without a heavy-lift shipyard crane, this process would be impossible, forcing a return to slower, less efficient building methods. The crane's role extends throughout the ship's lifecycle in the yard:

Hull Block Assembly: Lifting and joining pre-fabricated steel sections.

Engine Installation: Lowering multi-ton propulsion units into the ship's engine room.

Superstructure Placement: Installing bridges, funnels, and mast assemblies.

Outfitting: Loading containers, lifeboats, and other major equipment.

Ship Launching: In some yards, specialized cranes are used to directly lift and transfer completed vessels into the water.

Types of Shipyard Cranes

Not all shipyard cranes are created equal. Their design varies significantly based on their specific lifting capacity and mobility requirements.

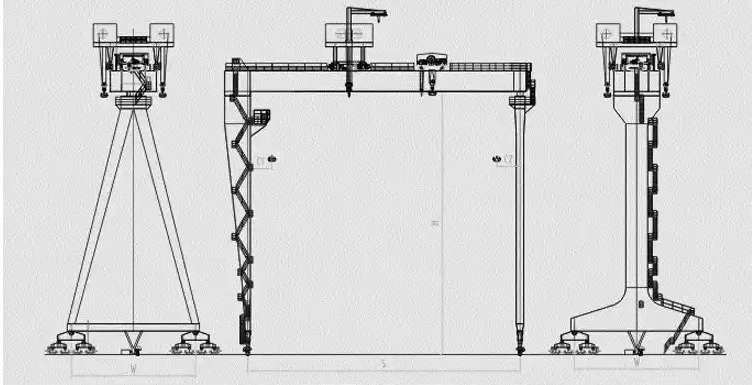

1.Goliath Gantry Cranes (Portal Cranes): These are the most iconic and capable. Running on parallel rails along the dock, they form a massive "portal" under which ships are built. Their key advantage is a wide, unobstructed work area and phenomenal lifting heights and capacities, often exceeding 1,000 tons. Some ultra-heavy-lift models can lift over 2,000 tons, capable of moving an entire cruise ship superstructure in one go.

2.Semi-Goliath Cranes: Similar to Goliaths but with one leg running on a rail and the other on a fixed runway or foundation on a workshop. They offer a compromise between high capacity and cost, ideal for serving both outdoor assembly areas and adjacent fabrication bays.

3.Portal Slewing Cranes: Featuring a rotating boom (slewing) on a portal frame that moves on rails, these cranes offer excellent flexibility and precision for lower-capacity lifts, often used for outfitting and servicing tasks.

4.Mobile Harbor Cranes: While not exclusive to shipbuilding, high-capacity mobile cranes are frequently used in smaller yards or for auxiliary tasks. Their versatility and ability to move quickly around the yard make them a valuable supplement to fixed cranes.

Key Engineering and Safety Features

Operating a shipyard crane is a high-stakes endeavor, demanding advanced engineering for safety and performance.

Lifting Capacity & Load Moment: The primary specification, measured in tons. Engineers meticulously calculate the load moment (weight x distance from the pivot) to ensure stability.

Precision Control Systems: Modern cranes use computerized, joystick-controlled drives that allow operators to make smooth, centimeter-perfect movements, even with swaying loads.

Anti-Collision & Load Monitoring: Redundant safety systems include automatic anti-collision sensors to prevent interference with other cranes or structures, and load moment limiters (LML) that prevent dangerous overloads.

Redundancy in Hoisting Systems: Critical components like brakes and motors often have backups to ensure a safe stop in case of a failure.

The Future: Automation and Smart Cranes

The shipyard of the future is increasingly digital, and crane technology is at the forefront. Trends include:

Automated & Remote Operation: Cranes can be pre-programmed for repetitive lifts or operated remotely from a control room, enhancing safety and efficiency.

Integration with Building Information Modeling (BIM): Crane paths can be simulated within the digital ship model to prevent clashes and optimize the assembly sequence before physical work begins.

Predictive Maintenance: Sensors monitor gearbox temperature, wire rope integrity, and motor performance, predicting maintenance needs before a breakdown occurs.

Conclusion

The shipyard crane is far more than a simple lifting device; it is the central pillar of modern, efficient shipbuilding. Its evolution—from steam-powered derricks to today's computer-controlled, thousand-ton giants—mirrors the advancement of the maritime industry itself. As ships grow larger and construction timelines tighter, the demand for even more capable, intelligent, and reliable shipyard cranes will only increase. They remain, quite literally, the towering force that lifts the world's fleet from blueprint to sea.

Frequently Asked Questions (FAQ) about Shipyard Cranes

Q1: What is the lifting capacity range of a typical shipyard crane?

Shipyard cranes cover a vast range, tailored to specific tasks:

Standard Duty: 50 - 150 tons for general outfitting and material handling.

Heavy Lift: 150 - 800 tons for block assembly and major component installation.

Ultra-Heavy Lift (Goliath): 800 tons to over 2,000 tons (and even beyond for specialized yards). The world's most powerful can lift upwards of 2,200 tons.

Q2: How do I choose the right type of crane for my shipyard or heavy-lift project?

Selection depends on several critical factors:

Maximum Lifted Load & Radius: Determine the heaviest single item and the farthest distance it needs to be placed.

Coverage Area & Obstacles: Assess if you need full dock coverage (favoring a Goliath) or a more localized work area.

Foundation & Rail Infrastructure: Goliath cranes require massive, reinforced concrete runways, while mobile options need strong paved surfaces.

Budget & Operational Flexibility: A large Goliath is a major capital investment; mobile or smaller gantry cranes offer more flexibility at a lower initial cost.

Future Expansion: Consider if your needs will grow, requiring a crane with reserve capacity.

Q3: What are the most important safety features in a modern shipyard crane?

Modern cranes integrate multiple redundant systems:

Load Moment Limiter (LML): The primary safety system that prevents crane overload by automatically cutting off unsafe movements.

Anti-Collision Systems: Uses sensors and software to prevent cranes or crane hooks from colliding with each other or fixed structures.

Redundant Braking & Hoisting Systems: Critical components have backups to ensure safe control in case of a failure.

Precision Control & Sway Control: Advanced drives allow smooth, millimeter-precise load placement, minimizing dangerous load swing.

Storm Safety Systems: Automatic rail clamps and wind-speed monitoring to secure the crane in adverse weather.

HENAN ZEHUA HEAVY INDUSTRY EQUIPMENT CO., LTD

Email: sale@zehuacranes.com

Website: [https://www.zehuacranes.com/]

Whatsapp:86-19562739544