For anyone involved in the yachting world—from marina operators and boatyard managers to yacht owners and builders—the sight of a large machine effortlessly lifting a vessel from the water is familiar. That machine is most likely a Travel Lift, also commonly known as a yacht handling crane, mobile boat hoist, or tire-type yacht hoist. It is the undisputed workhorse of modern marina and boatyard operations. But what exactly is it, and how does it work? This guide delves into the details.

1. Basic Introduction: The Marina's Essential Workhorse

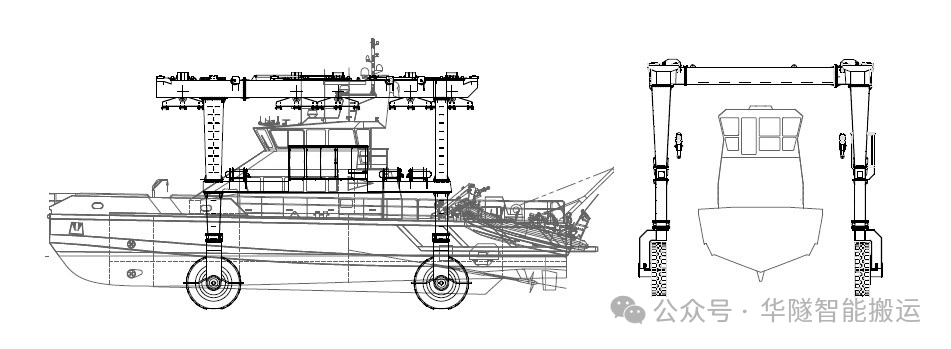

A Travel Lift is a specialized, self-propelled crane designed specifically for the safe and efficient launching, hauling, transportation, and storage of yachts, sailboats, and other small to medium-sized vessels. Unlike standard cranes, it features a wide, straddling "U" or "π"-shaped frame that drives over a vessel in the water or on land. Using adjustable, soft slings, it cradles the hull and lifts it completely, allowing for multi-directional movement on rubber tires.

Since its advent in the 1970s, the Travel Lift has revolutionized boat handling. Internationally, it has become the preferred method for 99% of professional marinas and boatyards due to its superior safety, versatility, and efficiency compared to traditional single-point lifting methods.

2. Product Parameters & Customization

Travel Lifts are highly customizable to fit specific operational needs. Key parameters include:

Lifting Capacity: Ranges widely, from smaller models handling 10 tons to massive units capable of lifting 800 tons or more. Always choose a capacity with a 20-30% safety margin above your heaviest vessel.

Span (Width between Legs): Adjustable to accommodate different vessel beam widths and ensure safe clearance.

Lift Height: Determines how high a vessel can be raised, crucial for stacking or accessing tall vessels like sailboats with high masts. The iconic "π"-shaped frame is often optimized specifically for high-mast sailboats.

Power Source: Diesel engines for outdoor yards or electric motors for zero-emission, quiet operation indoors or in eco-sensitive areas.

Tire Configuration & Steering: Multi-wheel configurations with independent steering allow for crabbing, 90-degree turns, and precise positioning in tight spaces.

| Parameter | Details |

|---|---|

| Product Name | Marine / Mobile Travel Lift (Boat Hoist / Gantry Crane) |

| Brand | ZEHUA |

| Model | MBH10Qt / MBH Model (4 Wheels Portable Gantry Crane) |

| Rated Loading Capacity | Custom, range: 5–1500 tons |

| Max. Lifting Height | As per customer demand |

| Span | 15 m or customized |

| Core Components | Engine, Bearing, Gearbox, Motor, Gear, PLC, Pump (varies by model) |

| Weight | Model dependent |

| Power Source | 3-phase AC 50Hz 380V |

| Certification | CE, ISO, TUV, GOST |

| Warranty | 12 months |

| Application | Port, Shipyard |

| Place of Origin | Henan, China |

3. How to Choose the Right Yacht Handling Crane

Selecting the correct Travel Lift is critical for safety and ROI. Consider these factors:

Vessel Specifications: Maximum weight (displacement), overall beam width, and overall height (including mast).

Primary Use Cases: Is it mainly for seasonal haul-outs, in-yard transport, maintenance, or new boat launches? Frequency of use matters.

Site Conditions: Available space in the yard and on the pier, ground surface (concrete, asphalt), and any spatial constraints.

Future-Proofing: Consider potential growth in the size of vessels you wish to service.

Features: Prioritize must-have features like wireless remote control, independent sling adjustment, and advanced safety systems.

4. Structural Features: Anatomy of a Travel Lift

A Travel Lift is a sophisticated integration of mechanical and hydraulic systems:

Main Frame (The "π" or "U" Shape): The robust steel structure that provides the span and strength. The "π" design offers superior height clearance.

Travel & Steering System: Independently driven and steered rubber-tired wheel groups. This allows for unparalleled mobility: forward/reverse, side-shifting (crabbing), and spot turning.

Lifting Mechanism: Consists of powerful hydraulic winches and hoists on each leg.

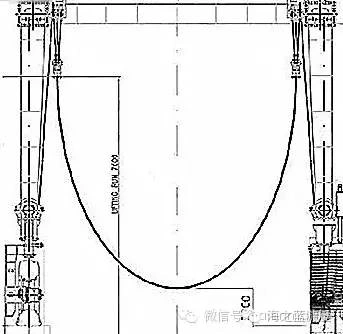

Lifting Slings: Wide, reinforced fabric belts that cradle the hull. They are adjustable to match the boat's specific lifting points, ensuring even weight distribution without pressure points.

Hydraulic System: Powers the lifting, lowering, and steering movements, offering smooth and controllable operation.

Control System: Modern lifts feature intuitive wired or wireless remote controls, allowing a single operator to manage all functions with precision.

5. Key Advantages & Benefits

Why has the Travel Lift become the global standard?

Superior Safety: Designed with a 120% overload protection system, it prevents lifting if the vessel is over capacity. The cradle-like lifting with soft slings eliminates hull distortion or "squeeze" damage common with single-point lifts.

Exceptional Maneuverability: Multi-directional movement allows for precise placement in crowded yards, maximizing storage space.

Vessel Versatility: Adjustable slings and spans can handle a vast array of hull shapes and sizes, from RIBs and sailboats to large motor yachts.

Operational Efficiency: One machine performs lifting, transporting, and positioning, reducing labor time and costs significantly.

Minimal Space Requirements: It doesn't require permanent dockside infrastructure like fixed cranes and doesn't occupy a slip during operation.

6. Operational Guide: Standard Lifting Procedure

A safe and standard operation follows this sequence:

Preparation: The Travel Lift is driven over the vessel in the water. Slings are positioned according to the vessel's designated lifting points.

Sling Attachment: Slings are carefully lowered and passed under the hull, ensuring they are centered and free of obstructions.

Lifting: The operator, via remote control, synchronously lifts the slings, gently cradling the vessel. The hull is lifted clear of the water.

Transport: The loaded Travel Lift is driven slowly and steadily to the desired land location—a storage stand, transport trailer, or work area.

Lowering & Placement: The vessel is precisely lowered onto its support, the slings are slackened and removed, and the Travel Lift drives away.

7. Maintenance Guide for Longevity

Regular maintenance is key to reliability and safety:

Daily/Pre-Use Checks: Inspect slings for cuts or wear, check tire pressure, look for hydraulic leaks, and test safety limit switches and brakes.

Scheduled Professional Maintenance: Follow the manufacturer's schedule for engine/hydraulic system servicing, structural inspection for cracks or corrosion, and electrical system checks.

Lubrication: Regularly grease all moving points, including sheaves, pins, and steering joints.

Winterization (if applicable): For seasonal operations, proper fluid management and component protection are essential.

Conclusion

The Travel Lift (Boat Crane, yacht handling crane) is far more than just a piece of machinery; it is the backbone of efficient, safe, and professional marina and boatyard operations. Its intelligent design—focusing on safety through overload protection, adaptability via independent sling control, and hull protection with soft slings—makes it the indispensable solution for yacht haul-out, transport, maintenance, and storage.

Investing in the right Travel Lift tailored to your needs directly translates to enhanced operational capacity, reduced risk of costly hull damage, and superior service for your clients.

Looking to upgrade your boat handling capabilities? Contact us today to discuss a customized Travel Lift solution for your specific requirements.

HENAN ZEHUA HEAVY INDUSTRY EQUIPMENT CO., LTD

Email: sale@zehuacranes.com

Website: [https://www.zehuacranes.com/]

Whatsapp:86-19562739544