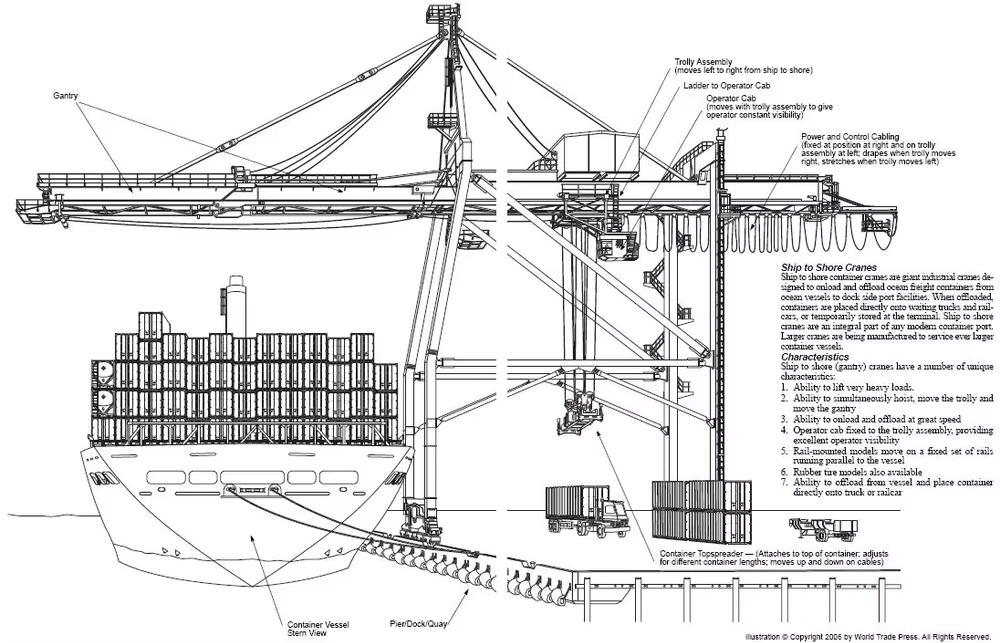

What is Quey Ship to shore Container Crane?

For port operators and terminal managers, selecting a Ship-to-Shore (STS) Crane is one of the most critical capital investment decisions. It's not just about buying a machine; it's about choosing a long-term partner for your port's productivity, efficiency, and profitability. Our STS Cranes are engineered with this holistic partnership in mind, delivering advantages that matter from your first inquiry to decades of reliable operation.

Why Our STS Cranes are the Superior Choice for Modern Terminals

We understand that your initial search focuses on proven performance and foundational quality. Our cranes are built to exceed these expectations.

Proven Legacy & Robust Engineering: Our cranes are synonymous with reliability. Featuring a heavy-duty, fatigue-resistant steel structure and premium-grade components from globally recognized brands, they are designed to withstand the most demanding 24/7 port environments, ensuring minimal structural stress and a long operational lifespan.

Optimized for Your Specific Operations: We don't believe in a one-size-fits-all solution. Whether you're servicing the latest Ultra-Large Container Vessels (ULCVs) or maximizing throughput for Panamax vessels, our cranes offer customizable outreach, lifting height, and lifting capacity (50-100+ tons). Advanced options like dual-container hoisting and anti-sway systems are available to dramatically boost your moves-per-hour (MPH) metrics.

Future-Ready Automation & Control: Transition towards higher efficiency and enhanced safety at your own pace. Our cranes are designed with automation-ready architecture, supporting features from remote operator assistance to fully automated stacking and transfer, protecting your investment for the future of port management.

Your Partner in Precision: From Inquiry to Final Quote

At this stage, you need a responsive and technically adept partner. We pride ourselves on a collaborative and transparent pre-sales process.

Expert-Led Consultation & Rapid Design: When you submit an RFQ, you connect directly with our senior engineering team. We engage in deep-dive discussions on your berth configuration, soil bearing capacity, and target productivity. You will receive preliminary CAD layout drawings and technical specifications tailored to your site within days, not weeks, ensuring the proposed solution is perfectly aligned with your operational reality.

Transparent & Competitive RFQ Process: We demystify crane costs. Our detailed quotations provide a clear breakdown, distinguishing between the base crane, optional automation features, and ancillary services. We focus on Total Cost of Ownership (TCO), highlighting how our energy-efficient drives and low-maintenance design translate into significant long-term savings, making our offer not just competitive in price, but superior in value.

Clarity on Compliance and Standards: We ensure every crane is designed and manufactured to meet or exceed international standards like FEM, ISO, and IEC, as well as your local regulatory requirements, giving you complete peace of mind.

Parameter of Quey Ship to shore Container Crane

| Parameter |

Value |

| Rated Load under Spreader |

40 t |

| Rated Load under Headlock |

50 t |

| Out Reach |

35 m |

| Rail Gauge |

16 m |

| Back Reach |

12 m |

| Hoisting Height Above Rail |

22 m |

| Hoisting Height Below Rail |

12 m |

| Hoisting Speed (Full Load) |

50 m/min |

| Hoisting Speed (Empty Spreader) |

100 m/min |

| Trolley Travel Speed |

150 m/min |

| Gantry Travel Speed |

30 m/min |

| Boom Hoisting Time |

6 min |

| Wheel Load (Working) |

400 kN |

| Wheel Load (Non‑working) |

400 kN |

| Power Supply |

10 kV, 50 Hz |

Securing Your Investment: A Commitment to Delivery and Long-Term Performance

The final decision hinges on trust and the assurance of seamless execution and lifelong support.

Iron-Clad After-Sales & Warranty Support: Our relationship begins at delivery. We offer comprehensive warranty packages, readily available spare parts, and flexible on-site maintenance contracts. Our global network of service engineers ensures rapid response times to minimize any potential downtime.

Seamless Project Execution & Financial Flexibility: We maintain complete transparency throughout manufacturing. You can schedule factory inspections to verify quality and track production progress with regular updates. To facilitate your procurement, we support various secure payment terms and can assist with financing solutions through our banking partners.

Guaranteed Operational Uptime & Efficiency: The ultimate test is performance on your quay. Our cranes are performance-verified to deliver the rated productivity and operational reliability promised. With robust construction and a proactive support system, we guarantee the long-term operational effectiveness that ensures your terminal remains competitive and profitable for years to come.

Ready to elevate your port's capabilities with a partner you can trust? Contact us today for a detailed technical datasheet or to schedule a confidential consultation with our STS Crane specialists.

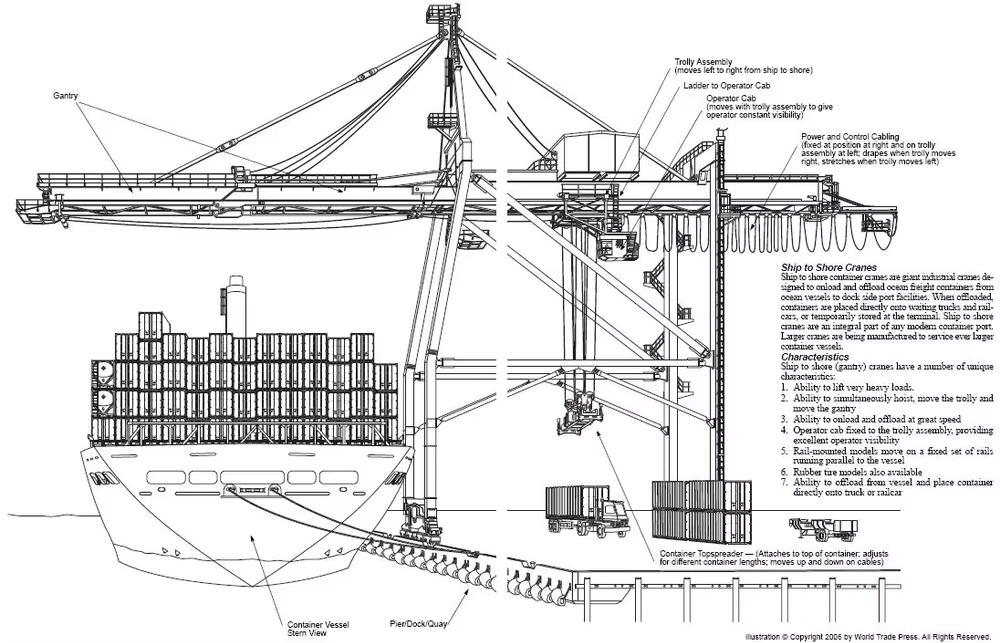

A Ship-to-Shore (STS) Crane is more than just a machine that moves boxes; it's the pivotal link in your supply chain's most critical transfer point. The true measure of a world-class STS crane is its adaptability and performance across your port's unique and demanding operational scenarios. Discover how our cranes are engineered not just to meet specifications, but to master the real-world challenges you face every day.

1. The Mega-Vessel Showdown: Taming the Giants of the Sea

The Scene: An Ultra-Large Container Vessel (ULCV), carrying over 24,000 TEUs, looms over your quay. Its deck is a sprawling metropolis of containers, stacked wide and high. The clock is ticking—every hour of port stay is a significant cost. You need a crane that doesn't just reach, but that dominates with speed, precision, and unwavering reliability.

How Our STS Crane Becomes Your Strategic Weapon:

Commanding Outreach & Intelligent Lift: With extended outreach (up to 72m+) and high-lift capabilities, our cranes effortlessly access the farthest and deepest cells of these leviathans. No container is out of reach, ensuring you maximize every vessel call.

Dual-Cycle Power for Unbeatable Turnaround: For the ultimate efficiency, our advanced twin-lift or dual-hoist systems allow you to move two 40-foot containers simultaneously. This isn't just an incremental gain; it's a game-changing boost to your Moves Per Hour (MPH), slashing vessel turn-time and enhancing your port's appeal to major shipping lines.

Smart Control for Pinpoint Precision: In tight spaces and under pressure, our advanced anti-sway and automated positioning systems ensure buttery-smooth container handling. This protects valuable cargo, prevents vessel damage, and reduces operator stress, guaranteeing both safety and speed.

*(For the Buyer's Mind: This addresses the long-term strategic need to service the largest clients. It answers the question: "Will this crane keep us competitive for the next 20 years?")*

2. The High-Speed Relay: Mastering the Transshipment Hub

The Scene: Your terminal is the central nervous system of global trade—a bustling transshipment hub. Containers are in constant motion, moving from deep-sea mother vessels directly to feeder ships with minimal dwell time. Here, reliability is as crucial as speed; a single crane breakdown can cascade into a logistical nightmare.

How Our STS Crane Ensures Uninterrupted Flow:

Engineered for 24/7 Endurance: We build our cranes not just for performance, but for persistence. Using premium, fatigue-resistant steel and globally-sourced, tier-one mechanical components, we deliver exceptional equipment availability. This means your high-velocity operations keep running, shift after shift.

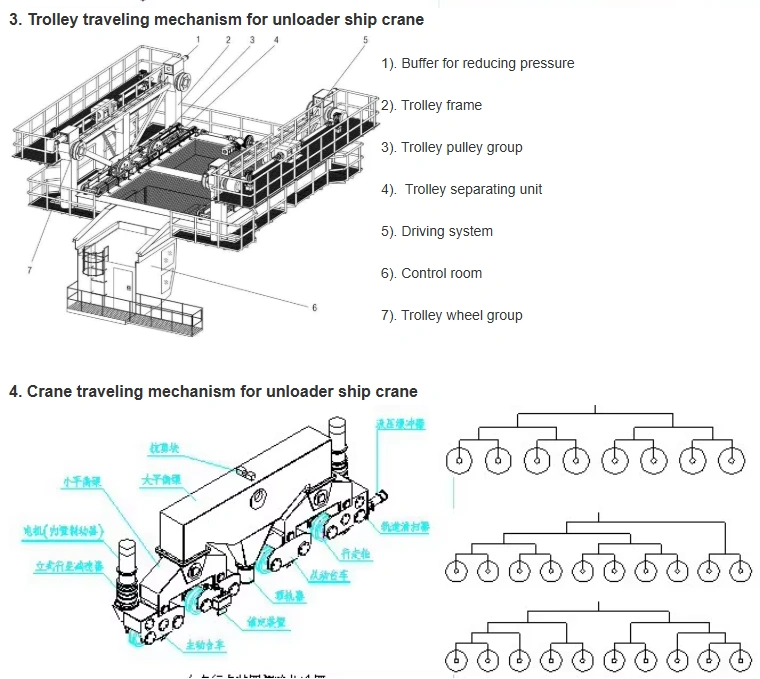

Accelerated Cycle Times: With optimized drive systems and high-speed trolley travel, our cranes are designed for rapid cycling. This translates directly into more containers moved per hour and a higher return on your berth investment.

The Automation-Ready Platform: To future-proof your hub, our cranes are designed as the ideal partner for automation. They seamlessly integrate with Remote Operation Stations (ROS) and Automated Guided Vehicles (AGVs), creating a continuous, efficient, and predictable flow from ship to yard.

(For the Buyer's Mind: This speaks directly to "Total Cost of Ownership" and operational risk. A reliable crane minimizes costly downtime and protects your reputation for efficiency.)

3. The Smart Expansion: Unlocking More from Your Existing Berth

The Scene: Your port is landlocked or built on legacy infrastructure. The cost of building a new berth is prohibitive. Your challenge is to increase capacity and efficiency within your current footprint—requiring a crane that is not just powerful, but also intelligent in its design.

How Our STS Crane Delivers a Custom-Fit Solution:

Tailored Engineering for Constrained Sites: We excel at brownfield solutions. Our team will engineer a crane with a specific rail span, wheel load distribution, and back-reach to work in harmony with your quay's load-bearing capacity, avoiding the need for massively expensive civil reinforcement.

Strategic Boom Selection: We provide expert consultation on the optimal boom design—whether it's the weight-saving efficiency of a lattice boom for maximum reach on a weaker quay, or the robust, low-maintenance profile of a box boom for simpler upkeep.

Modernization & Uprating Services: Already have cranes? We can breathe new life into your existing fleet through strategic upgrades—replacing hoist machinery, installing new control systems, and extending booms. This approach delivers a dramatic performance uplift at a fraction of the cost of a new crane.

(For the Buyer's Mind: This demonstrates partnership and financial savvy. It shows we provide innovative solutions to maximize your budget and solve physical constraints, proving we're more than just a manufacturer.)

From Scenario to Solution: Our Collaborative Process

Understanding your application is the first step. Delivering a crane that masters it is our promise. Our process is designed to build your confidence at every stage.

Phase 1: In-Depth Analysis & Bespoke Proposal - We don't just take an order; we conduct a needs analysis, studying your vessel profiles, berth data, and operational bottlenecks. You'll receive a customized performance simulation and layout drawing, proving the solution before a single part is built.

Phase 2: Transparent Collaboration & Value-Driven Quoting - You work directly with our project engineers to refine every detail. Our detailed RFQ response provides a clear cost-benefit analysis for every feature, ensuring you make an informed investment without hidden surprises.

Phase 3: Guaranteed Execution & Lifelong Partnership - We validate our quality through invited factory inspections and provide transparent production updates. This is backed by comprehensive after-sales support, training, and spare part guarantees, ensuring your crane delivers peak performance for its entire lifecycle.

Ready to see how our STS cranes perform in your specific scenario? Contact us to arrange a virtual consultation and a personalized performance modeling session. Let's engineer your success, together.

Product manual

Product manual