What is General Metallurgy Overhead Crane?

The General Metallurgy Overhead Crane represents the pinnacle of heavy-duty lifting engineering, specifically designed to thrive in the most challenging metal processing applications. From scorching foundries to corrosive steel mill environments, this crane delivers unmatched reliability where ordinary lifting equipment would fail.

Advanced Features for Demanding Applications

Exceptional Load Capacity

Handle heavy loads from 5 to 500 tons with precision stability

Specially engineered for smelting, casting, forging, and rolling operations

Robust girder structures designed for continuous heavy-duty cycles

Superior Heat & Corrosion Resistance

Specialized alloy steel components withstand temperatures up to 180°C

Multi-layer protective coatings combat abrasive dust and chemical exposure

Heat-resistant electrical systems and thermal protection packages

Precision Control Systems

Smooth variable frequency drive for accurate load positioning

Anti-sway technology for safe transport of molten materials

Multiple control options: pendant, cabin, or remote operation

Rigorous Safety Compliance

Dual braking systems with emergency stop functionality

Overload protection and limit switches certified to international standards

FEM/ISO compliant designs with comprehensive safety packages

Customized Solutions for Your Specific Needs

We understand that every metallurgical operation has unique requirements. That's why we offer:

Design Flexibility

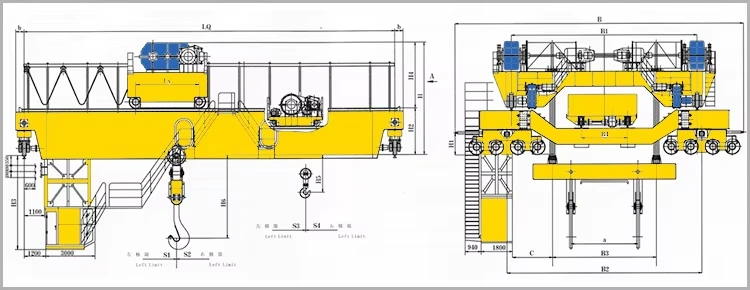

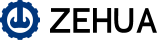

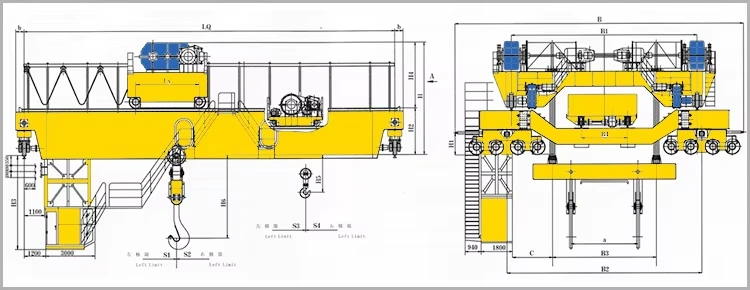

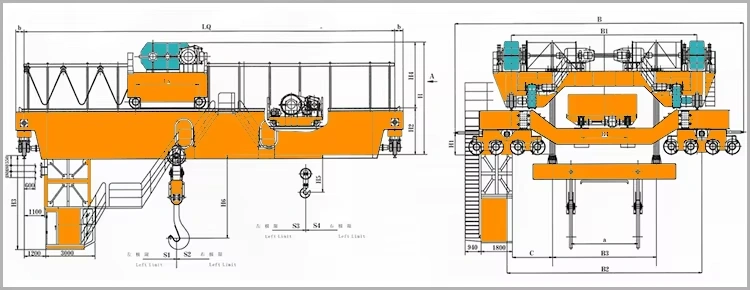

Single and double girder configurations

Custom span lengths up to 35 meters

Specialized lifting attachments and fixtures

Professional Technical Support

Rapid response to RFQs with detailed quotations within 24 hours

3D design layouts and facility planning assistance

Expert guidance on crane selection and specification

Quality Assurance You Can Trust

Proven Performance

CE, FEM, and ISO certification standards

Comprehensive quality control documentation

Industry-leading warranty and support packages

Global Manufacturing Excellence

State-of-the-art production facilities

Strict quality control at every manufacturing stage

Worldwide installation and commissioning support

Technical Specifications Overview

Lifting Capacity: 5-500 tons (custom designs available)

Working Environment: -20°C to +65°C (high-temperature packages available)

Control Systems: Advanced frequency conversion technology

Safety Features: Comprehensive protection systems meeting international standards

| Parameter |

Specification / Value |

| Loading Capacity (Main) |

5–350 t (range covers both models) |

| Loading Capacity (Aux) |

32 t / 40 t |

| Span |

10.5–38 m |

| Lifting Height |

Customized / 20 m / 22 m |

| Lifting Speed (Main) |

Varies with capacity / 6.84–7.5 m/min |

| Lifting Speed (Aux) |

9.1–12 m/min |

| Trolley Traveling Speed |

73–79.7 m/min |

| Crab Traveling Speed |

38 m/min |

| Working Class |

A7 / A8 |

| Working Temperature |

–20 to +60 °C |

| Power Supply |

3-phase AC, 50/60 Hz, 380V |

| Control Voltage |

DC 36V / 48V |

| Motor Protection Class |

IP54 / IP55 / IP65 |

| Control Method |

Cabin, wireless remote, pendant push button |

| Safety Devices |

Buffer, overload protection, power failure protection |

| Max. Wheel Load |

343–405 kN |

| Total Power |

426.5–484.5 kW |

| Recommended Crane Rail |

QU120 |

| Application Areas |

Factory, workshop, warehouse, power station, logistics |

| Painting Color |

Yellow, Red, or Customized |

Application Scenes of Metal Processing Casting Overhead Crane

molten steel glowing at 1600°C, needing precise transfer from furnace to mold. Or imagine massive forged components requiring millimeter-perfect positioning in your assembly line. This is where the General Metallurgy Overhead Crane becomes your most reliable partner, engineered to excel where ordinary equipment fails.

Transform Your Critical Metal Processing Operations

Steel Mills & Foundries

Safely transport molten metal in ladles with absolute stability and control

Handle glowing ingots and billets with heat-resistant components that withstand extreme temperatures

Precision-position heavy molds and casting equipment with smooth, anti-sway movement

Forging & Stamping Facilities

Lift and position massive dies and tooling with exact placement accuracy

Handle heavy pressed components without deformation or surface damage

Maintain consistent performance in high-vibration forging environments

Smelting & Refining Operations

Efficiently move raw materials including metal ores, scrap, and additives

Transport processed ingots and finished metal products with reliable consistency

Operate flawlessly in corrosive atmospheres where chemical vapors are present

Automotive & Aerospace Metalworks

Assemble large structural components with precision alignment capabilities

Handle expensive aerospace alloys and delicate finished parts without damage

Support just-in-time manufacturing with reliable, uninterrupted operation

Metal Recycling & Scrap Processing

Sort and transport bulky scrap metal with powerful lifting capacity

Work continuously in dusty, abrasive environments with minimal maintenance

Handle magnetic and non-magnetic materials with specialized lifting attachments

Heavy Fabrication Workshops

Support welding operations by positioning large structural steel sections

Assist in machining centers by handling oversized workpieces

Enable efficient assembly of industrial machinery and equipment

Your Journey to Superior Lifting Performance - From First Inquiry to Long-Term Partnership

Initial Research: When Quality and Reliability Matter Most

We understand you're comparing multiple suppliers while worrying about:

"Will this crane withstand our extreme conditions day after day?"

"Is this manufacturer reputable with proven metallurgy experience?"

"Does the price represent true value, not just the lowest cost?"

Our Assurance to You:

Industry-Proven Performance: Join leading metal producers who've trusted our cranes for decades

Transparent Quality: Every component is certified and documented - no compromises

Competitive Value: Premium engineering that reduces your long-term operating costs

Detailed Comparison: When You Need Answers, Not Just Specifications

As you move closer to decision time, you need a partner who responds promptly and professionally:

"Will they understand our specific operational challenges?"

"Can they provide custom designs that fit our unique layout?"

"Are their engineers knowledgeable about metallurgical processes?"

Our Commitment During Your Evaluation:

24-Hour Technical Response: Get detailed answers and design concepts when you need them

Application Engineering: Experts who speak your language and understand metal processing

Custom Layout Services: 3D facility planning that optimizes your workflow

Transparent Pricing: Comprehensive quotes with no hidden costs

Final Decision: Ensuring This Investment Protects Your Operations for Years

Before you approve the purchase, you're rightfully concerned about:

"What happens if we need service at 3 AM during critical production?"

"Can we verify their manufacturing quality before shipment?"

"Will this crane still perform efficiently five years from now?"

Eliminating Your Final Concerns:

Comprehensive Service Network: 24/7 emergency support with guaranteed response times

Factory Acceptance Program: Visit our facility, meet our team, witness quality control

Long-Term Performance Guarantee: Maintenance programs that ensure decades of reliable service

Financial Flexibility: Multiple payment options and financing solutions available

Experience the Difference in Every Critical Lift

Our metallurgy cranes don't just lift weights - they elevate your entire operation:

Morning shift: Confidently handle molten metal with absolute safety and control

Afternoon operation: Move heavy dies and tooling with precision that reduces setup time

Night production: Continue heavy lifting operations with reliability that never sleeps

Ready to See How We Can Transform Your Metal Processing Operations?

Contact our metallurgical lifting specialists today for:

🔧 Free facility assessment

📊 Customized operational analysis

🎯 Tailored quotation and layout

Don't just choose a crane - choose a partnership that understands metal processing from the inside out.

Product manual

Product manual