Product manual

Product manual

- Product Overview

- Application Scenario

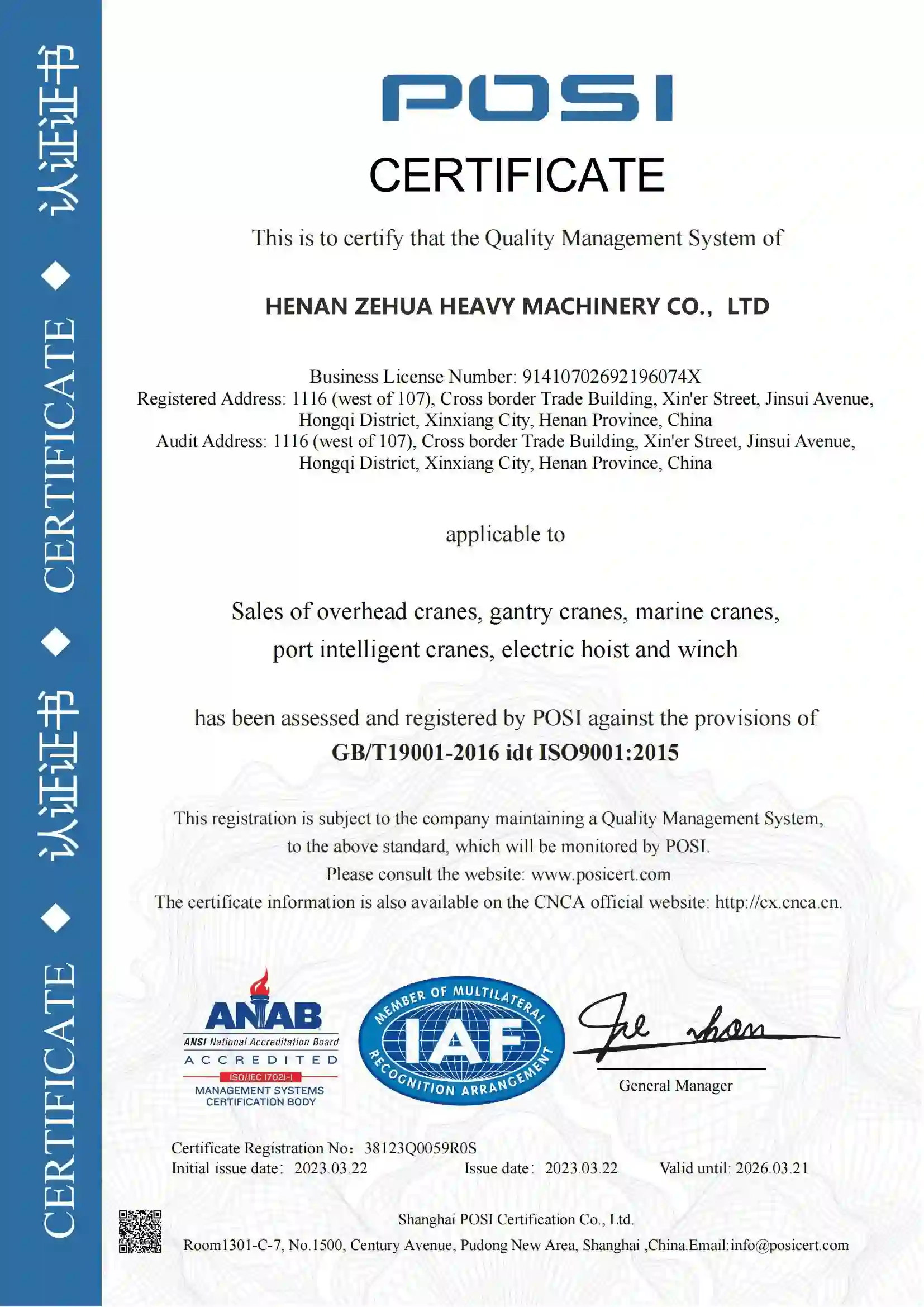

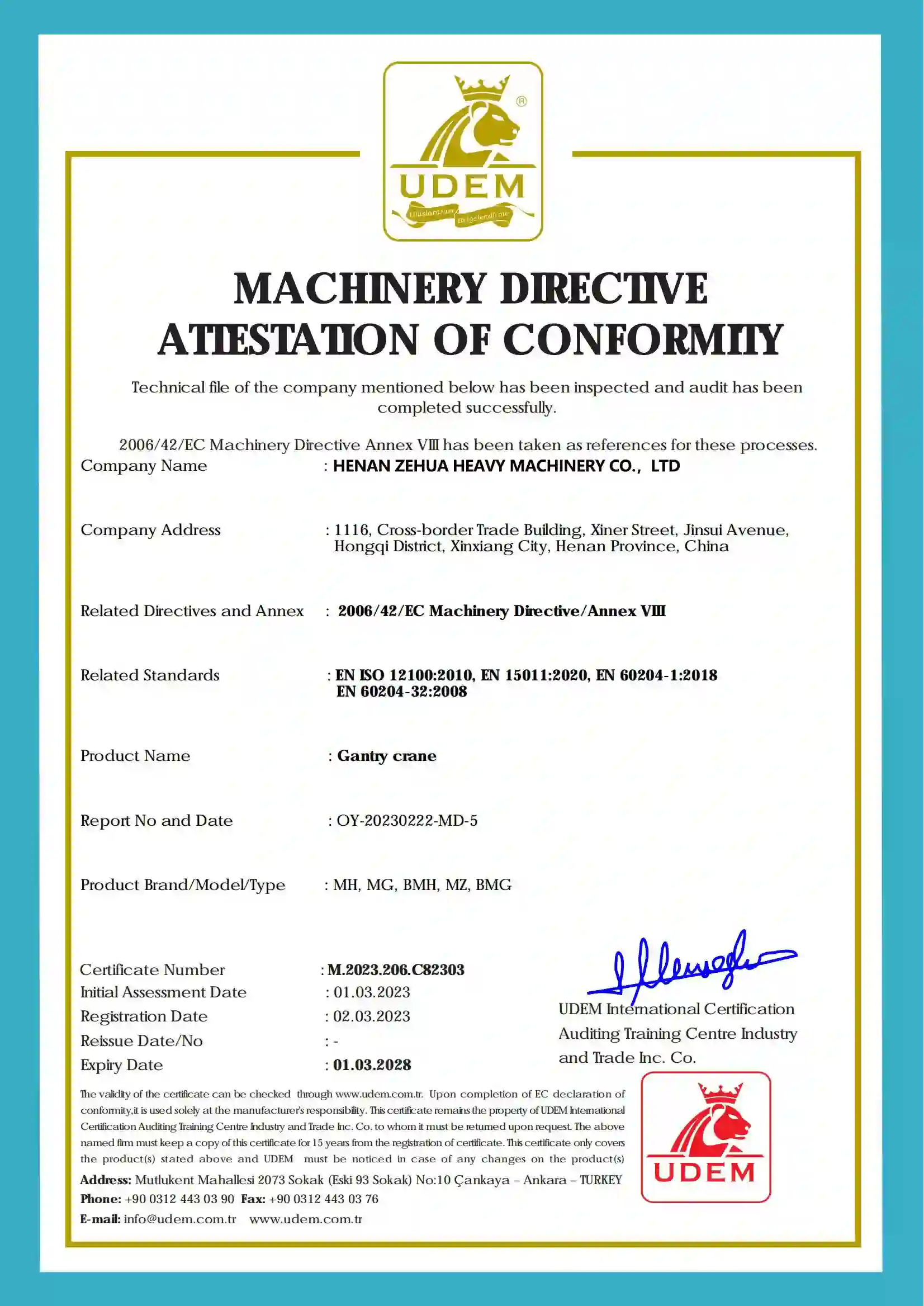

- Certificate

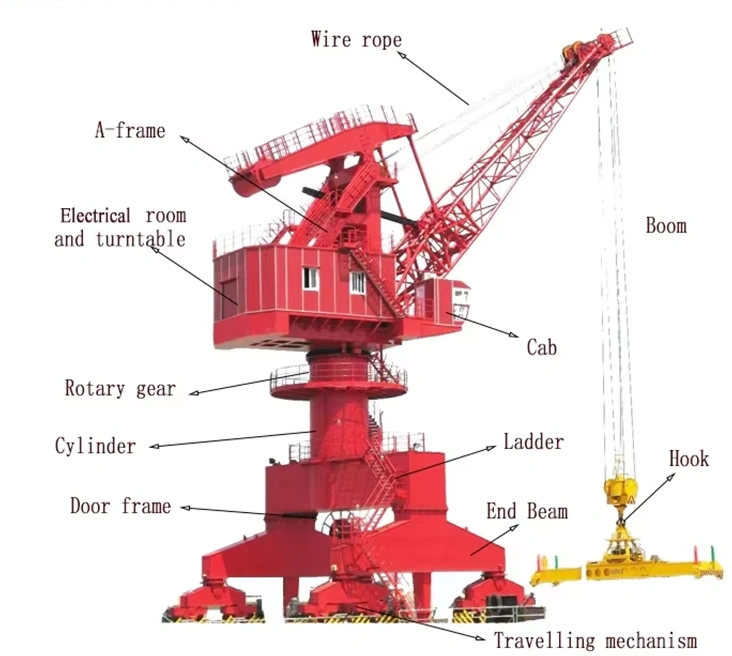

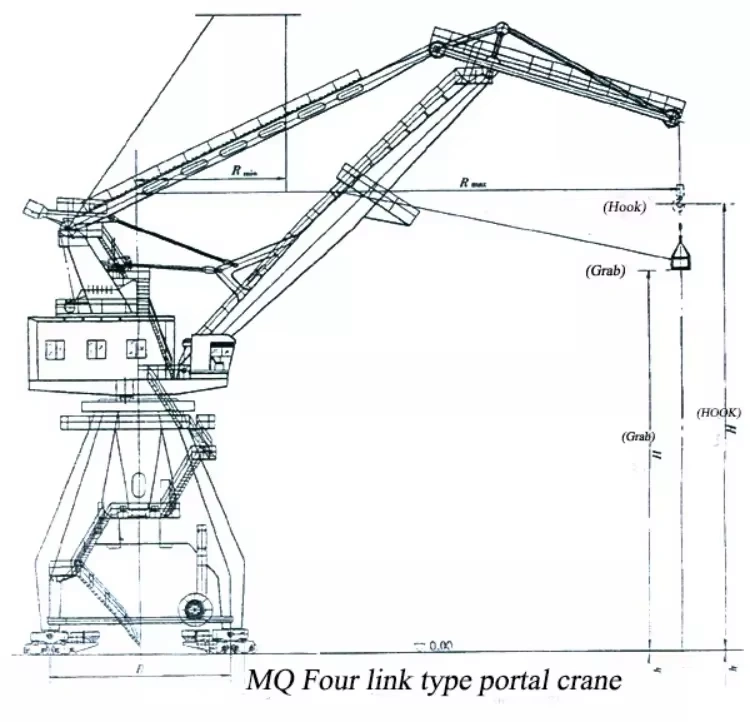

What is a four link portal crane?

When investing in a portal crane, you need more than just machinery—you need a reliable partner for your operations. Our Four-link Portal Crane is designed to deliver unmatched performance, durability, and efficiency, tailored to meet the demands of ports, docks, and industrial yards. Here’s why it stands out:

Core Features of Four Link Portal Crane

Beyond general promises, true value lies in the details. Our Four-link Portal Crane is packed with engineered features designed to deliver tangible operational and financial benefits. Here’s a deeper look at what sets it apart:

1. Optimized Four-Link Luffing Mechanism

Precision Load Control: Unlike single-link systems, the four-link configuration creates a near-horizontal path for the load during luffing (boom raising/lowering). This means the cargo moves horizontally with minimal vertical sway, allowing for pinpoint positioning and significantly faster, safer container spotting.

Reduced Drive Power & Energy Savings: This optimized mechanical path drastically lowers the power required by the luffing machinery. The result is up to 30% lower energy consumption during cyclic loading and unloading operations, directly cutting your operational costs.

2. Robust Box-Girder Boom & Portal Structure

High Torsional Rigidity: The main boom and the portal (gantry) frame are constructed from high-grade, welded steel box girders. This design provides exceptional resistance to twisting and bending forces under dynamic loads, ensuring structural integrity and long-term alignment.

Extended Service Life: The robust design incorporates a high safety factor, reducing metal fatigue over time. This translates to a longer operational lifespan and lower lifetime maintenance costs.

3. High-Performance Hoisting & Trolley System

Dual-Speed Hoisting Motor: Provides both high-speed for empty hook movement and low-speed, high-torque power for lifting full loads. This enhances operational efficiency without compromising safety.

Smooth Trolley Traverse: The trolley runs on precisely machined rails on the boom girder, powered by high-torque motors. This ensures smooth acceleration and deceleration, preventing load swing and enabling precise load placement, even in high-wind conditions.

4. Advanced Drive and Control Integration

Frequency Control for All Motions: All major movements—hoisting, luffing, trolley traversing, and gantry travel—are equipped with AC frequency drives. This allows for incredibly smooth speed control, soft starts/stops, and reduced mechanical stress on gears and brakes.

Intelligent PLC-Based Control System: The crane is managed by a programmable logic controller (PLC) with a state-of-the-art operator cabin. Features include real-time monitoring, fault diagnostics, and overload protection, empowering your operators to work with maximum efficiency and safety.

5. Built-In Safety and Maintenance Features

Multi-Layer Safety Devices: The system includes redundant protections: an overload limit switch, hoist height limiters, anti-collision systems for multiple cranes, and emergency stop buttons at strategic locations.

Easy Access for Maintenance: Walkways, ladders, and service platforms are strategically placed for easy and safe access to all key components like motors, gearboxes, and sheaves. This simplifies routine inspections and reduces maintenance downtime.

6. Corrosion Protection for Harsh Environments

Multi-Stage Surface Treatment: For port and marine applications, the steel structure undergoes rigorous surface preparation, including shot blasting, followed by a multi-coat epoxy paint system. Critical areas receive extra protection, significantly extending the time before first major repainting is required.

Your Next Step: A Solution Tailored to You

These features are not just specifications on a page; they are direct answers to real-world operational challenges like high energy bills, maintenance downtime, and safety concerns. We invite you to discuss your specific site layout and cargo handling requirements. Let us provide you with a detailed design proposal and a transparent, competitive quotation.

Contact us today to request a technical datasheet, schedule a live video demo, or speak directly with our project engineers.