Real-World Application & Case Study

Project: Offshore Wind Farm Converter Station Installation, South China Sea

Client Challenge: Install a 4,200-ton offshore electrical converter platform foundation (jacket) in a deep-water site with strong currents and significant wave action.

Our Solution: Deployment of our 5000-ton DP2 Floating Crane Barge.

Execution: The vessel used its DP2 system to transit to and hold precise position at the installation site without anchoring. The active heel compensation system maintained stability while lifting the massive jacket from the transport barge. The full-revolution crane then expertly maneuvered and lowered the structure onto pre-installed piles with centimeter-level accuracy.

Result: The operation was completed 48 hours ahead of schedule, demonstrating how advanced vessel capabilities translate into direct project savings and risk mitigation. This successful installation is a benchmark for the region's growing offshore wind sector.

Floating Crane Barges for Ships: Your Premier Solution for Heavy-Lift Maritime & Offshore Operations

For project managers, marine engineers, and offshore contractors, the critical challenge of installing, removing, or transporting massive structures in open water is met with one essential asset: the Floating Crane Barge. More than just a vessel, it is a mobile, high-capacity lifting platform designed to execute the most demanding offshore and nearshore projects with precision, safety, and efficiency.

While we offer a comprehensive range of floating cranes classified under the latest GB/T 6974.7-2022 standard (and not classified as special equipment in many jurisdictions), our flagship model exemplifies the cutting-edge capabilities we provide.

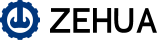

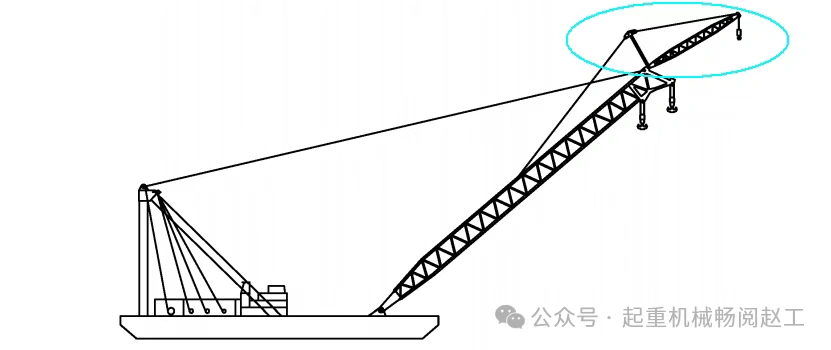

Flagship Model Spotlight: The "Atlas-Class" 5000-Ton DP2 Heavy Lift Vessel

This vessel represents the pinnacle of modern maritime heavy-lift engineering, specifically engineered for complex deep-water operations such as offshore wind farm installation, subsea structure placement, and major port construction.

Imagine a lifting solution that goes where the work is, overcoming the limitations of fixed infrastructure and unpredictable water levels. The Floating Portal Crane isn't just a piece of machinery; it's a transformative asset for any operation dependent on marine logistics. Explore the diverse scenarios where its versatility becomes your greatest competitive advantage.

Ideal for Various Applications

Container handling at seaports and inland terminals

Loading/unloading at shallow-water docks and fishing harbors

Offshore construction and logistics support

-

Emergency response and salvage operations

1. Bustling Commercial Ports & Container Terminals

The Challenge: A mammoth container ship arrives, but tidal variations or congested berths make quick turnaround difficult. Fixed cranes can't adapt, causing costly delays.

Our Solution in Action: Our Floating Portal Crane maneuvers effortlessly into position, its buoyant base making water depth irrelevant. With its powerful hoist and precise, 360-degree rotation, it efficiently unloads standard and heavy-load containers, seamlessly transferring them from ship to shore. It's the key to accelerating your port's throughput, handling vessels of all sizes with agility that fixed cranes simply cannot match.

2. Constrained & Shallow-Water Docks & Inland Waterways

The Challenge: Your dock serves smaller barges, fishing fleets, or coastal traders in shallow waters. Traditional equipment lacks the reach or mobility, forcing you to rely on slower, more expensive methods.

Our Solution in Action: Navigate right up to smaller vessels with confidence. The crane's floating design provides stable lifting power where others can't go, effortlessly moving palletized goods, construction materials, or specialized cargo directly onto the deck. It brings big-port capabilities to localized operations, maximizing your dock's utility without massive investment in fixed infrastructure.

3. Dynamic Shipbuilding & Vessel Repair Yards

The Challenge: Installing heavy engine blocks, pre-fabricated ship sections, or oversized propellers requires pinpoint accuracy and immense lifting power, often over water.

Our Solution in Action: Position the crane as a stable, floating workhorse alongside dry docks or quaysides. Its high load capacity and adjustable boom allow for the careful placement of massive components, streamlining the construction and repair process and enhancing worksite safety by reducing manual handling.

4. Critical Offshore Support & Emergency Response

The Challenge: You need to deliver heavy equipment to offshore platforms, support bridge construction, or respond to salvage operations where there is no fixed docking point.

Our Solution in Action: As a self-contained lifting and logistics hub, the crane can be towed to any location. It serves as the primary tool for placing materials on platforms, handling construction piling, or assisting in recovery missions, providing unmatched operational readiness when and where it's needed most.

Ready to See How It Fits Your Operation?

Let's move beyond generic specs. Contact us for a personalized application analysis, a site-specific design layout, and a competitive quotation that demonstrates true value. Tell us your challenge, and we'll show you the solution.

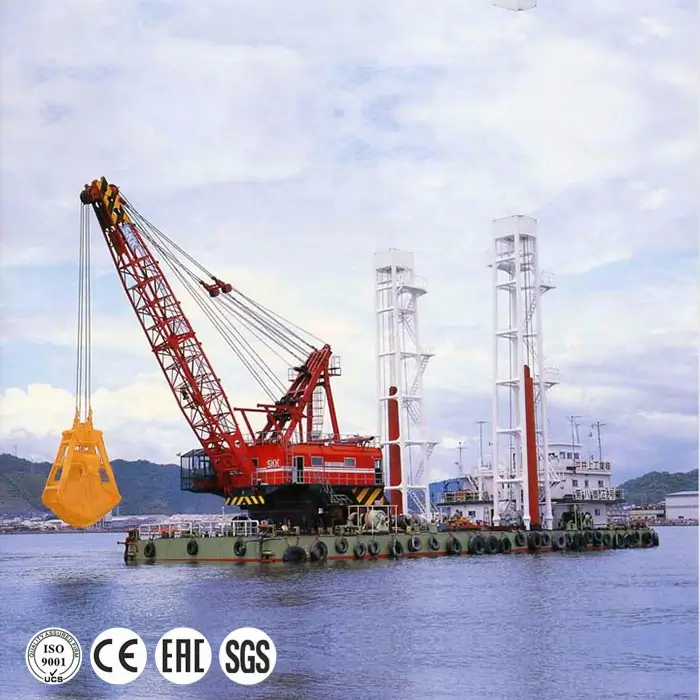

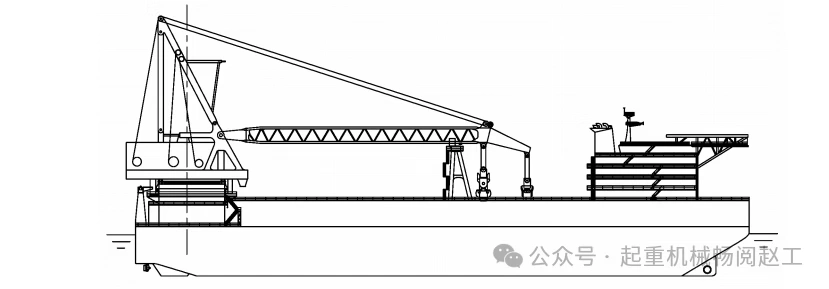

Product manual

Product manual