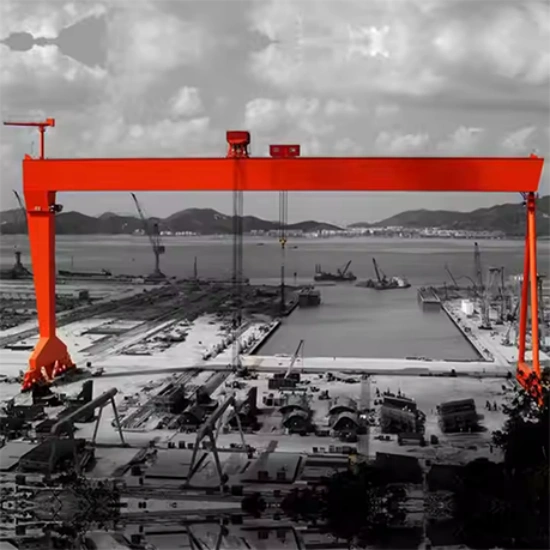

In the complex world of shipbuilding, your gantry crane is more than just equipment—it's the backbone of your production line. It dictates your workflow efficiency, impacts project timelines, and ultimately, influences your profitability. At Korig, we engineer our Shipbuilding Gantry Cranes not just to meet specifications, but to deliver a seamless, reliable, and high-return partnership from your first inquiry to years of operation.

Why Our Shipbuilding Gantry Crane is Your Superior Choice

We understand that your initial search focuses on proven performance and uncompromising quality. Our cranes are built to excel where it matters most.

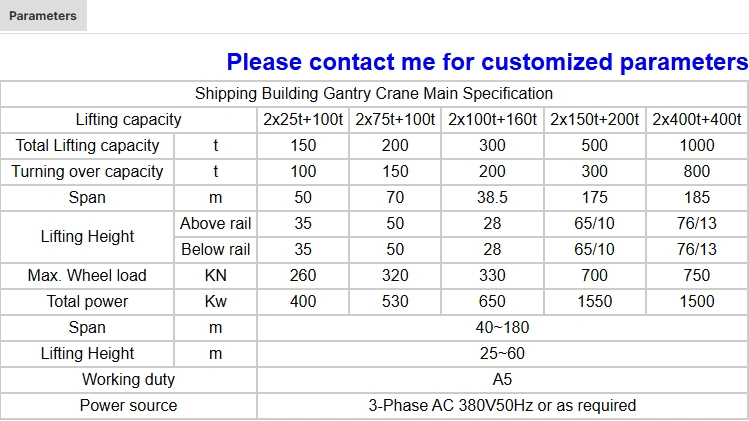

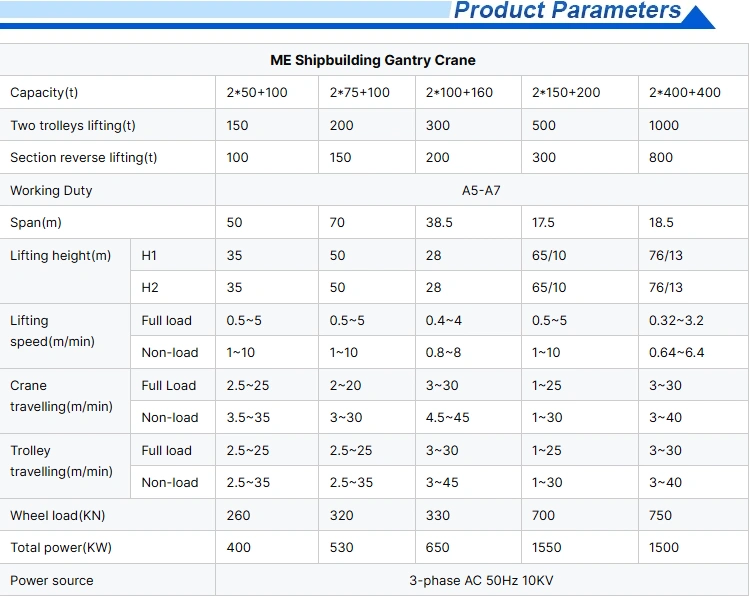

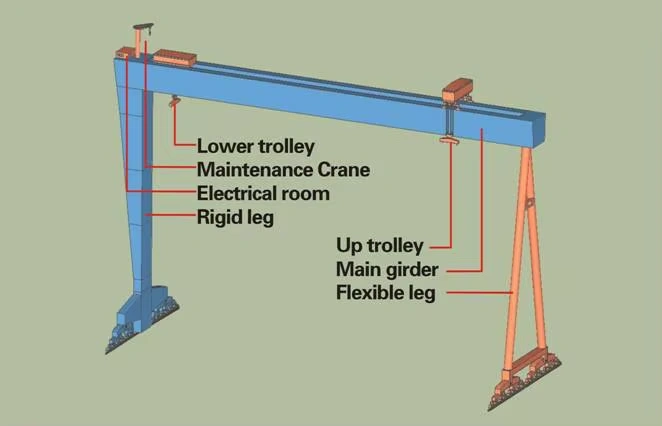

Unmatched Lifting & Maneuvering Capabilities: Go beyond basic lifting. Our cranes are designed for the entire hull assembly process—from the fragmented transport of massive sections to precise end-to-end joining and critical in-air turnover operations. This ensures you can adjust any fragment to the exact welding position required, streamlining your entire assembly line.

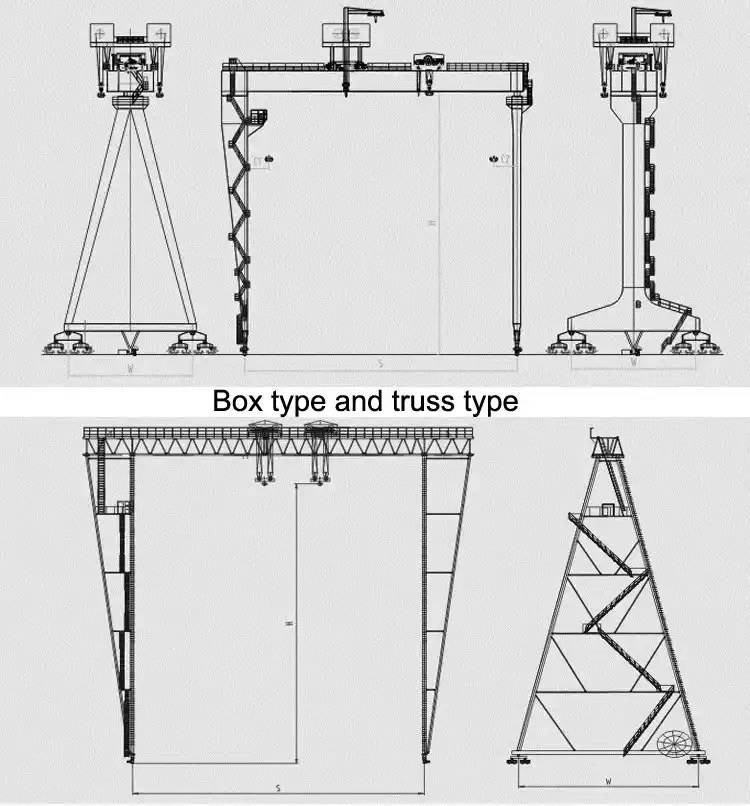

Robust, Long-Lasting Construction: Built with high-strength steel and a reinforced double-girder design, our cranes are engineered to withstand the corrosive, high-cycle demands of a shipyard environment. This isn't just about lifting capacity; it's about structural integrity over a 20+ year lifespan, minimizing long-term maintenance costs.

Precision Control for Delicate Operations: Handling multi-ton ship sections requires finesse. Our integrated Variable Frequency Drives (VFD) ensure exceptionally smooth acceleration and deceleration, allowing for pinpoint positioning that protects your valuable components and ensures perfect alignment.

Your Partner in the Decision-Making Process

We know that between initial interest and adding to your cart, you need a responsive and expert partner. Our process is designed to build your confidence.

Expert & Timely Consultation: When you request a quote (RFQ), you don't just get a price. You get a dedicated project manager who understands shipbuilding parameters. We ask the right questions about your dock layout, workflow, and specific challenges to provide a solution, not just a product.

Fast, Customized Design Proposals: Time is money. We pride ourselves on providing preliminary design layouts and CAD drawings promptly, giving you a clear, visual understanding of how our crane will integrate into and enhance your operation.

Transparent & Competitive Value Analysis: Our pricing is not just about being competitive; it's about demonstrating value. We break down our quotes to show you where your investment is going—from premium components to intelligent features that reduce your operational costs.

Securing Your Investment with Confidence

The final decision hinges on trust and the assurance of long-term support. We solidify our partnership with unwavering post-sale commitment.

Comprehensive After-Sales Support: Your investment is protected by a robust warranty, readily available spare parts, and access to a global network of technical support. We ensure your crane maintains peak performance throughout its lifecycle.

Flexible Procurement & Logistics: We offer flexible payment terms and take full responsibility for packaging and shipping, ensuring your crane arrives on site safely and on schedule, anywhere in the world.

Welcome Plant Inspection & Progress Updates: We encourage you to visit our manufacturing facility to see our quality control processes firsthand. Once an order is placed, we provide regular production progress updates, so you are never in the dark.

Guaranteed Operational Uptime & ROI: The ultimate advantage of a Korig crane is its long-term reliability. By minimizing downtime, reducing energy consumption through efficient drives, and delivering consistent performance, we ensure your crane is a asset that contributes positively to your bottom line for decades.

Ready to elevate your shipbuilding capabilities? Contact our engineering team today for a free, no-obligation consultation and a custom-designed solution for your shipyard.

In the high-stakes world of shipbuilding, where precision meets immense power, your choice of a gantry crane defines your operational ceiling. It's the pivotal asset that impacts your project timelines, safety standards, and bottom line. At ZEHUA HEAVY MACHINE, we engineer our Shipbuilding Gantry Cranes to be more than just equipment; we deliver a partnership built on Chinese manufacturing excellence, direct-factory value, and unwavering reliability.

Engineered for Uncompromising Performance & Durability

We understand that your initial search is driven by the need for a crane that won't fail under pressure. ZEHUA cranes are built to excel where it matters most.

Proven Capability for Mega-Blocks: We specialize in cranes with the robust lifting capacity and structural integrity to handle the largest hull sections. Our designs ensure smooth, controlled lifting, precise in-air turnover, and accurate positioning, directly streamlining your hull assembly process and reducing man-hours.

Built to Endure the Harshest Environments: Constructed from high-tensile steel and featuring a reinforced double-girder design, a ZEHUA crane is engineered to withstand the corrosive, salt-laden air and demanding cycles of a shipyard. This translates to a longer service life and lower total cost of ownership.

Precision Control for Critical Operations: Protecting multi-million dollar ship components is paramount. Our cranes are equipped with advanced Variable Frequency Drives (VFD) for exceptionally smooth acceleration and deceleration, allowing for millimeter-precision positioning that safeguards your assets.

Your Direct-from-Factory Advantage: Transparent & Expert Collaboration

When you engage with ZEHUA, you are connecting directly with the source. This eliminates markups and ensures your voice is heard by the engineers who build your solution.

Direct Engineering Support: When you submit an RFQ, you communicate directly with our technical team. This ensures your specific requirements for span, lifting height, and duty cycle are understood and optimized from the start, avoiding costly oversights.

Rapid, Custom Design Proposals: We respect your project timelines. Our team is committed to providing preliminary CAD drawings and layout plans promptly, giving you a clear and professional visual of how our crane will integrate into your dock.

Exceptional Value, No Compromises: As a direct manufacturer, we provide highly competitive pricing without sacrificing quality. Our quotes are transparent, detailing how our robust construction and premium components deliver superior long-term value over cheaper alternatives.

Securing Your Investment with ZEHUA's Reliable Partnership

The final decision is about trust. ZEHUA stands by its products with a comprehensive support system designed to give you complete peace of mind.

Comprehensive Warranty & After-Sales: Your investment is protected by a clear warranty and supported by a readily available inventory of spare parts. Our global service network ensures you have access to technical support when you need it.

Flexible Procurement & Progress Visibility: We offer flexible payment terms to suit your project cash flow. Furthermore, we provide regular production updates with photos and videos, so you can witness your crane being built and have full confidence in the progress.

Welcome to Our Factory: We proudly invite you to inspect our ZEHUA manufacturing facility in China. See our quality control processes, our skilled workforce, and the raw materials that go into every crane. Building trust face-to-face is our priority.

Guaranteed Uptime for Long-Term ROI: A ZEHUA crane is an investment in your yard's productivity. By ensuring relentless reliability and efficiency, we help you minimize downtime, meet critical deadlines, and strengthen your competitive edge for years to come.

Application Scenarios: The ZEHUA Crane in Action Across Your Shipyard

Imagine a single, powerful system that elevates efficiency at every stage of your shipbuilding process. A ZEHUA gantry crane is engineered to be that strategic asset.

Hull Block Assembly: Seamlessly transport and position massive pre-fabricated sections with the stability and precision required for perfect alignment, accelerating your welding phase.

Critical Engine & System Installation: Safely lower high-value engines and propulsion systems into the engine room with the smooth, controlled hoisting that protects your most crucial assets.

In-Air Hull Turnover: Revolutionize workflow by safely rotating hull blocks 360 degrees, providing your teams immediate access for welding and inspection, drastically improving quality and safety.

Dry Dock Maintenance & Repair: Execute rapid component replacement—from propellers to rudders—during tight dry-dock schedules, ensuring vessels return to service faster.

Fabrication Workshop Hub: Act as the central logistics nerve center, moving large pre-assembled modules like pipe racks and electrical panels with ease, eliminating bottlenecks.

Ready to experience the ZEHUA difference? Contact our engineering team today for a free, no-obligation consultation and a custom-designed solution that meets the exact demands of your shipyard.

Crane Wireless Remote ControFor more details

Crane Wireless Remote ControFor more details Intelligent Stacker CraneFor more details

Intelligent Stacker CraneFor more details KBK Stacking CraneFor more details

KBK Stacking CraneFor more details Drive MotorsFor more details

Drive MotorsFor more details