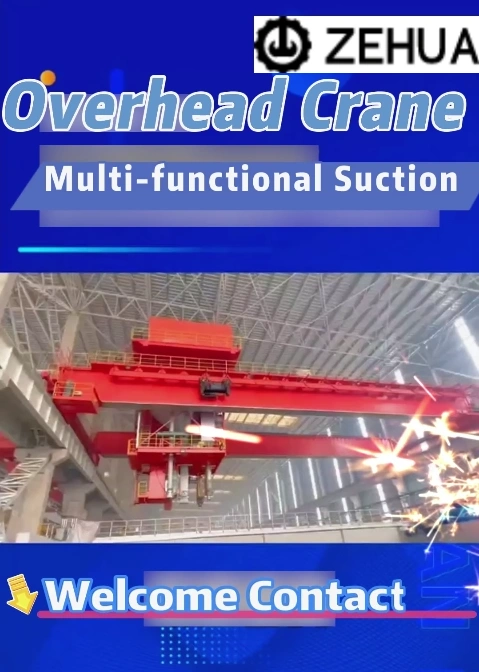

For aluminum producers seeking a specialized overhead crane solution for anode baking furnace operations, the Multi-Functional Baking Crane delivers precision, durability, and advanced functionality tailored to demanding industrial environments. Engineered to handle critical tasks—from loading raw anode blocks and distributing filler coke to vacuum extraction and unloading baked anodes—this crane ensures seamless integration into your production line while maximizing operational uptime and safety.

Key Advantages for Your Investment Decision

1. Uncompromising Quality and Engineering Excellence

Robust Structural Design: Built with high-strength steel (Q355B) and optimized via FEM analysis, the crane offers long-term reliability under heavy-duty cycles (A8 class), reducing structural risks and maintenance needs.

Proven Component Integration: Modular subsystems, including 3-in-1 geared motors and reinforced trolleys, ensure smooth operation and simplified servicing, minimizing lifecycle costs.

2. Advanced Automation and Operational Efficiency

Smart Control Systems: Equipped with PLC and variable frequency drives, the crane supports semi- or fully automated workflows, enabling precise anode handling and filler management with minimal operator intervention.

High-Capacity Material Handling: Vacuum suction systems achieve up to 80 m³/h throughput, with reinforced pipelines and dust removal efficiency (emissions ≤10mg/m³) to maintain workshop cleanliness.

3. Customization for Your Facility’s Needs

Layout Adaptability: Choose from trolley or lower girder configurations to optimize space in existing or new facilities. The 4-wheel travel system reduces wheel load, lowering building structure costs.

Flexible Duty Options: Designed for 24/7 operation, with customization available for anode clamp capacity (e.g., 2×6t) and filler coke handling parameters (granule size 0.8–5mm, heat resistance up to 600°C).

4. Eco-Friendly and Safe Operation

Closed-Loop Dust Control: Multi-stage cyclone and bag filtration systems capture particulate matter, ensuring compliance with environmental standards and protecting worker health.

Fail-Safe Mechanisms: Overload protection, emergency braking, and redundant cooling systems mitigate operational risks in high-temperature environments (e.g., baking furnaces).

Why Partner with Us? A Client-Centric Approach

Pre-Purchase: Transparent Consultation and Tailored Solutions

Expert Technical Support: Our engineers provide detailed design layouts and RFQ responses within 24–48 hours, clarifying crane specifications (e.g., travel mechanisms, hoist configurations) to match your furnace layout and throughput goals.

Competitive Pricing without Compromise: We balance cost-efficiency with premium components, offering value-driven quotes that reflect your operational priorities—whether prioritizing automation, duty class, or emission controls.

Mid-Process: Streamlined Coordination and Design Accuracy

Rapid Design Visualization: Receive CAD drawings and 3D models promptly, ensuring alignment with your facility’s spatial and operational constraints.

Direct Engineer Communication: Discuss technical parameters—from filler granule temperature tolerance to PLC logic—with specialists who understand anode baking processes deeply.

Post-Order: Reliable Execution and Long-Term Support

On-Time Delivery Tracking: Regular production updates and optional factory inspections keep you informed of assembly progress.

Comprehensive After-Sales Service: Installation supervision, operator training, and readily available spare parts (e.g., filter bags, motor assemblies) minimize downtime.

Flexible Payment and Warranty Terms: Secure transactions with milestone-based payments and a 12–24-month warranty on core components.

Industries Served

Aluminum Smelting & Electrolysis Plants

Carbon Anode Manufacturing

Metallurgy and Mining Operations

Raw Material Processing Facilities

Optimize your anode baking line with a crane that combines engineering rigor, environmental compliance, and adaptable automation. [Contact us] for a customized proposal, including design schematics, lifecycle cost analysis, and case studies from global aluminum producers.

In the heart of modern aluminum production facilities, where extreme temperatures and continuous operation demand equipment that can withstand the most challenging conditions, the Multi-Functional Baking Crane stands as a critical backbone of anode baking furnace operations. This specialized overhead crane doesn't just move materials—it orchestrates precise, efficient handling of anode blocks and filler materials throughout the demanding baking process, ensuring your production line maintains peak performance while meeting stringent environmental standards.

Core Application Environments

1. Aluminum Smelting & Electrolysis Plants

Precision Anode Handling: Imagine seamlessly transferring raw, unbaked anode blocks into 400-600°C furnace pits with millimeter-level accuracy, then efficiently extracting perfectly baked anodes for the next production phase—all while maintaining continuous operation cycles.

Intelligent Filler Management: Visualize the crane's vacuum system precisely distributing granular coke between anode blocks and furnace walls, then systematically recovering and recycling the material, creating a closed-loop process that minimizes waste and maximizes material utilization.

2. Carbon Anode Manufacturing Facilities

End-to-End Process Integration: From receiving raw carbon blocks to positioning them in baking pits, then transporting finished anodes to cooling stations, the crane serves as the central material handling solution that connects your entire production workflow.

Dust-Free Operation: In facilities where airborne particles can compromise product quality, the integrated multi-stage filtration system maintains workshop air quality while handling high-temperature materials.

3. Metallurgical & Mining Operations

Multi-Purpose Material Handling: Beyond anode-specific tasks, the crane's auxiliary lifting capabilities support various workshop needs—from equipment maintenance to raw material transfer—making it a versatile investment for diverse industrial applications.

High-Temperature Adaptation: Engineered to operate reliably in environments where filler materials reach 450°C (with short-term exposure to 600°C), ensuring consistent performance where standard cranes would fail.

Operational Excellence in Critical Scenarios

Continuous Production Environments

24/7 Operation Ready: With A8 duty classification and robust construction, the crane maintains reliable performance through continuous shifts, handling 2×6t anode loads with precision and stability.

Automated Workflow Support: Picture your operation transitioning to semi-or fully automated anode handling, with PLC-controlled movements ensuring repeatable accuracy and reducing human error in high-temperature environments.

Space-Constrained Facilities

Compact Design Advantage: In facilities where every square meter counts, the crane's optimized structure and customizable configurations (including下沉式trolley options) maximize usable space without compromising capacity or functionality.

Reduced Structural Load: The 4-wheel travel system distributes weight efficiently, potentially lowering your building construction costs while maintaining heavy-duty performance.

Why Our Baking Crane Delivers Beyond Basic Requirements

For Initial Evaluation: Trust in Proven Performance

Industry-Proven Reliability: With installations in aluminum smelters worldwide, our cranes demonstrate consistent performance in the most demanding baking furnace applications.

Transparent Value Proposition: We provide detailed technical documentation and case studies showing real-world performance metrics—not just specification sheets.

During Comparison Phase: Expert Support When You Need It

Rapid Technical Response: Submit your facility layout and receive customized design proposals within 48 hours, complete with load calculations and integration recommendations.

Clear Cost-Benefit Analysis: Our quotations include detailed breakdowns of operational savings—from reduced maintenance intervals to energy efficiency gains—helping you justify the investment.

At Decision Stage: Assurance Through Comprehensive Support

Production Transparency: Optional workshop visits and weekly progress reports keep you connected to your equipment's manufacturing journey.

Long-Term Performance Guarantee: Beyond standard warranties, we offer performance verification services and preventive maintenance programs to ensure your crane operates at peak efficiency for years.

Flexible Commissioning Support: From supervised installation to operator training and spare parts inventory planning, we ensure smooth integration into your operations.

Beyond Equipment: A Partnership for Your Production Success

We understand that purchasing a specialized baking crane involves more than comparing specifications—it's about finding a reliable partner who understands anode baking processes and can support your operation through the equipment's entire lifecycle. From the initial technical consultation through decades of operation, we provide the expertise and support that keeps your production running smoothly.

Ready to see how our Multi-Functional Baking Crane can transform your anode handling operations? Contact us today for a facility-specific application analysis, including 3D operational simulations and detailed ROI calculations based on your production volumes and operational requirements.

Product manual

Product manual